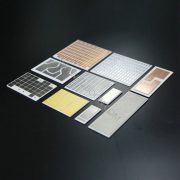

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

- Description

- Inquiry

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

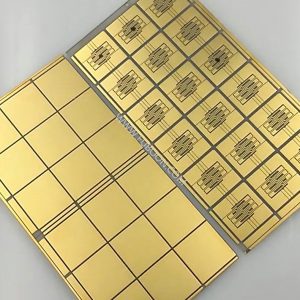

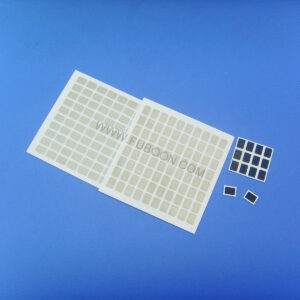

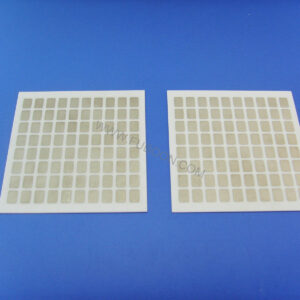

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of aluminum nitride ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

DBC ceramic substrate/for electronic heating devices/Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate /FUBOON

3.May be structured just like PCB boards or IMS substrates to get etched wiring;

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

Aluminium Nitride Material Properties | ||||

Properties | FUB-AN180 | FUB-AN200 | FUB-AN220 | |

Color | Gray | Gray | Beige | |

Main Content | 96%ALN | 96%ALN | 97%ALN | |

Main Characteristics | High Thermal Conductivity,Excellent Plasma Resistance | |||

Main Applications | Heat Dissipating Parts,Plasma Resistance Parts | |||

Bulk Density | 3.30 | 3.30 | 3.28 | |

Water Absorption | 0.00 | 0.00 | 0.00 | |

Vickers Hardness(Load 500g) | 10.00 | 9.50 | 9.00 | |

Flexural Strength | >=350 | >=325 | >=280 | |

Compressive Strength | 2,500.00 | 2,500.00 | – | |

Young’ Modulus of Elasticity | 320.00 | 320.00 | 320.00 | |

Poisson’s Ratio | 0.24 | 0.24 | 0.24 | |

Fracture Toughness | – | – | – | |

Coefficient Linear Thermal Expansion | 40-400 degree Celsius | 4.80 | 4.60 | 4.50 |

Thermal Conductivity | 20 degree Celsius | 180.00 | 200.00 | 220.00 |

Specific Heat | 0.74 | 0.74 | 0.76 | |

Thermal Shocking Resistance | – | – | – | |

Volume Resistivity | 20 degree Celsius | >=10-14 | >=10-14 | >=10-13 |

Dielectric Strength | >=15 | >=15 | >=15 | |

Dielectric Constant | 1MHz | 9.00 | 8.80 | 8.60 |

Loss Tangent | *10-4 | 5.00 | 5.00 | 6.00 |

Remark: The value is just for review, different using conditions will have a little difference. | ||||

Related Products

AlN Aluminum Nitride Ceramic Metallized DPC Substrate with Au/Cu Coating

Alumina Al2O3 Metallizing Ceramic Parts

Alumina Al2O3 Metallizing Ceramic Parts

High Temperature Resistance Alumina Metallized Ceramic Ring

High Temperature Resistance Alumina Metallized Ceramic Ring

Aluminum Nitride AlN Metallized DBC Substrate/Plate/Disc with Au

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

High Voltage Alumina Metalized Ceramic Insulator

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube

Metallized Ceramic Housing for Power Semiconductors

Metallized Ceramic Housing for Power Semiconductors

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

Metallized Al2O3 Ceramics Substrate Ni/Au Plating

Metallized Ceramic Tube Vacuum Feedthrough Insulator

Metallized Ceramic Tube For Vacuum Feedthrough Insulator