High Voltage Alumina Metalized Ceramic Insulator

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube

- Description

- Inquiry

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube

The prime features of alumina metalized ceramics

1. High bonding/brazing strength with ideal vacuum tightness between the assembly

2. With diamond-like hardness to be 85 HRV and superb compressive strength

3. Great insulation strength and volume resistivity that fit for various high voltage high current applications

4. Chemical stability, anti-aging even if it works in a variety of harsh environments, free of rust forever.

5. Over 276 times wear resistance in comparison with stainless steel, it leads to a long service lifespan.

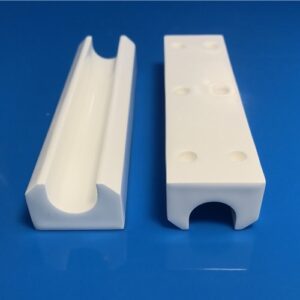

High Voltage Alumina Metalized Ceramic Insulator

The key parameters capability of metalized ceramics

| Leak rate | ≤1×10-11 Pa•m3 / s | Metal layer tensile strength | ≥ 150Mpa |

| Volume Resistivity | ≥108Ω•cm | CTE | (6.5 ~ 8.0) × 10-6 /°C |

| Insulation strength | ≥18kV/mm (D•C) | Dielectric constant | 9~10(1MHz, 20°C) |

| Cosmetic quality: 1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination | |||

The description of the metalized ceramics

1. It’s made of 95% aluminum oxide ceramics which has superb mechanical, electrical, and thermal properties.

2. The metallic layer will be applied to a certain surface of ceramic parts which cured by high temperature;

3. Then the metallic layer will adhere to the section tightly to achieve ceramic to ceramic, ceramic to metal jointing.

4. Jointing type of metallization

A. Ceramic base + Silver ( Ag) plating, 10~ 80um thick

B. Ceramic base + Molybdenum ( Mo – Mn) metallization, 20 ~ 40um thick

C. Ceramic base + Molybdenum (Mo – Mn) + Nickle (Ni) plating, Mo/Mn: 20 ~ 40um thick, Ni: 2~6um thick

D. Ceramic base + Tungsten ( W) + Gold (Au) plating, W: 20~40um thick, Au: 0.2um thick

Overview of Main Physical Properties:

1.Good electrical insulation

2.High mechanical strength

3.Excellent wear resistance

4.Excellent corrosion resistance

5.Low dielectric constant

Overview of Main Applications:

1.Pump seals and other components

2.Wear resistant inserts

3.Insulating washers or bushings

4.Semiconductor components

5.Aerospace components

6.Automotive sensors

7.Electrical or electronic insulators

Related Products

Al2o3 ceramic shaft piston plunger

Al2o3 ceramic shaft piston plunger

Ceramic valve ball and seat components

Ceramic valve components.Including valve ball(O-port and V-port),Seats and other parts for full-lined ceramic ball valve.

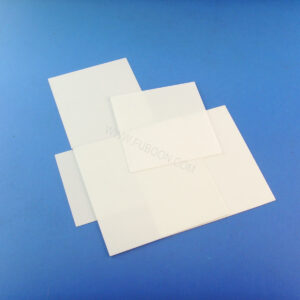

Al2O3 Ceramic Substrate

Al2O3 Ceramic Substrate for electronics

Alumina ceramic components

Alumina ceramic components

Alumina Ceramic Industrial Nozzle

Ceramic nozzle for welding and sand blast

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector

Furnace Kiln High Temperature Resistant Alumina Ceramic Tube

High-temperature alumina ceramic tube

Al2O3 Ceramic Steel Shaft

Alumina Al2O3 Ceramic Steel Shaft

Ceramic Igniter for Wood Pellet Stove

Ceramic Igniter for wood pellet stove/soldering/water heater

99% Alumina ceramic OD300 Large diameter liner

99% Alumina ceramic OD300 Large diameter liner