AlN Aluminum Nitride Ceramic Metallized DPC Substrate with Au/Cu Coating

- Description

- Inquiry

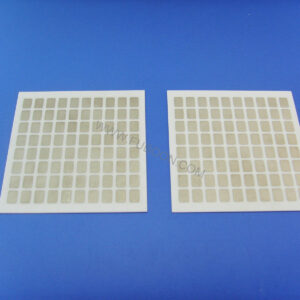

Aluminum Nitride Ceramic Metallized DPC Substrate with Au/Cu Coating

Aluminum Nitride Ceramic Metallized DPC Substrate

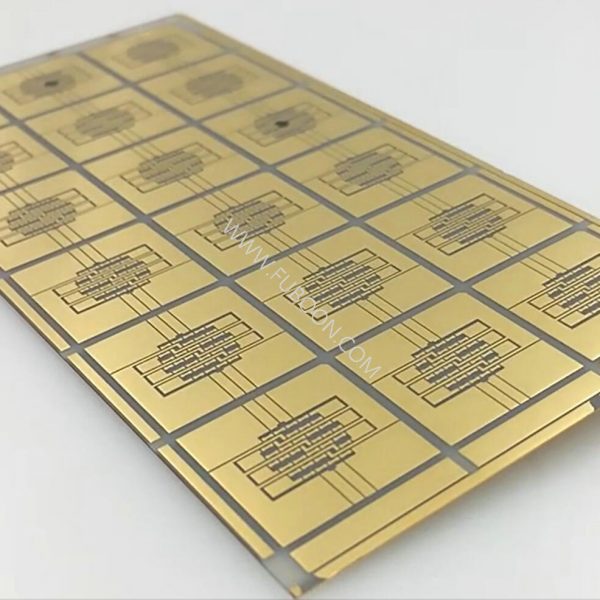

DPC (Direct Plated Copper) Substrate Introduction:

Mainly by evaporation, magnetron sputtering and other surface deposition process to carry on the substrate surface metallization, first under the condition of vacuum sputtering, titanium, and then is copper particles, the plating thickness, then finish making line with ordinary PCB craft, and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating, wet deposition,Exposure development, etching and other processes.

DPC Ceramic Substrate Advantages: > In terms of shape processing, DPC ceramic substrate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. > The crystal performance of the metal is good; > The flatness is good; > The line is not easy to fall off; > The line position is more accurate, the line distance is smaller, reliable and stable, can be through the hole and other advantages.

DPC Disadvantages: It can only make thin plate (thickness < 300μm), and its cost is high, the output value is limited, resulting in frequent shipment time can not be on time.

Aluminum Nitride Ceramic Metallized DPC Substrate

Aluminium Nitride Material Properties | ||||

Properties | FUB-AN180 | FUB-AN200 | FUB-AN220 | |

Color | Gray | Gray | Beige | |

Main Content | 96%ALN | 96%ALN | 97%ALN | |

Main Characteristics | High Thermal Conductivity,Excellent Plasma Resistance | |||

Main Applications | Heat Dissipating Parts,Plasma Resistance Parts | |||

Bulk Density | 3.30 | 3.30 | 3.28 | |

Water Absorption | 0.00 | 0.00 | 0.00 | |

Vickers Hardness(Load 500g) | 10.00 | 9.50 | 9.00 | |

Flexural Strength | >=350 | >=325 | >=280 | |

Compressive Strength | 2,500.00 | 2,500.00 | – | |

Young’ Modulus of Elasticity | 320.00 | 320.00 | 320.00 | |

Poisson’s Ratio | 0.24 | 0.24 | 0.24 | |

Fracture Toughness | – | – | – | |

Coefficient Linear Thermal Expansion | 40-400 degree Celsius | 4.80 | 4.60 | 4.50 |

Thermal Conductivity | 20 degree Celsius | 180.00 | 200.00 | 220.00 |

Specific Heat | 0.74 | 0.74 | 0.76 | |

Thermal Shocking Resistance | – | – | – | |

Volume Resistivity | 20 degree Celsius | >=10-14 | >=10-14 | >=10-13 |

Dielectric Strength | >=15 | >=15 | >=15 | |

Dielectric Constant | 1MHz | 9.00 | 8.80 | 8.60 |

Loss Tangent | *10-4 | 5.00 | 5.00 | 6.00 |

Remark: The value is just for review, different using conditions will have a little difference. | ||||

Related Products

Metallized Ceramic Alumina Insulator for Brazing

High Temperature Resistance Alumina Metallized Ceramic Ring

High Temperature Resistance Alumina Metallized Ceramic Ring

Alumina Al2O3 Metallizing Ceramic Part

Alumina Al2O3 Metallizing Ceramic Part

Alumina Al2O3 Metallizing Ceramic Parts

Alumina Al2O3 Metallizing Ceramic Parts

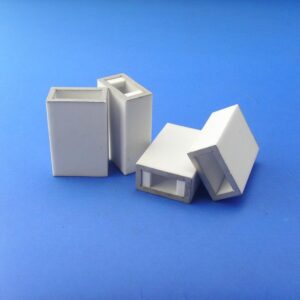

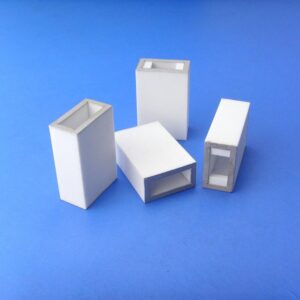

Metallized Ceramic Housing for Power Semiconductors

Metallized Ceramic Housing for Power Semiconductors

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

Aluminum Nitride AlN Metallized DBC Substrate/Plate/Disc with Au

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Insulating Metallized Ceramic Frame

Electrical 99% Alumina Ceramic Metallized DBC Substrate

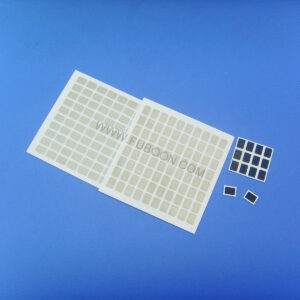

Ceramic substrates for LED