> Metal/alloy ceramic metallized

> Screen Printing

> Roll Printing

> Hand Painting

> Air Brush Spraying

> Immersion

> Centrifugal Coating

> Needle Painting

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

- Description

- Inquiry

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes

The Ceramic Surfaces for Brazing, the surface must be metallized.

Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher.

* More solid, durable hermetic seal and better electrical insulation

* Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments

* High mechanical strength, less fracture when applied to high vibration and high g-load conditions

* Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Overview of Main Physical Properties:

1.Good electrical insulation

2.High mechanical strength

3.Excellent wear resistance

4.Excellent corrosion resistance

5.Low dielectric constant

Descriptions of Metallization Processing:

| Metallization Processing (See Process Description Below) | Outer Diameter and Inner Diameter Banding |

| Brush | |

| Screen Printing | |

| Spray | |

| Needle | |

| Base Metallization Materials | Moly Manganese |

| Tungsten Manganese | |

| Moly Tungsten Manganese | |

| Materials for Metallization | Aluminum Oxide |

| Beryllium Oxide (Restrictions Apply) | |

| Metallization Characteristics/Benefits | Low Temperature Firing |

| Universally Applicable | |

| Process Speed | |

| Uniform Coating, Thickness and Density | |

| No substrate deformation | |

| Metallization Equipment | Domestic Furnaces |

| Industry Focus | Department of Defense |

| Department of Energy | |

| Solar Product Manufacturing | |

| Aerospace | |

| Biomedical | |

| Communications | |

| Computer and Electronics | |

| Vacuum Electronics | |

| Medical | |

| Military | |

| Semiconductor | |

| Optical | |

| Intended Applications for Metallization Products | Traveling Wave Tubes |

| Vacuum Electronic Devices | |

| Medical Devices | |

| Photon Machines | |

| Neutron Generators | |

| X-Ray Tubes | |

| Klystrons | |

| High Vacuum Feed Through | |

| Relay Insulators | |

| E-Beam Technology |

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Related Products

Alumina liner tube sleeve cylinder for pump

Alumina liner tube/sleeve/cylinder for pump

Ceramic Igniter for Wood Pellet Stove

Ceramic Igniter for wood pellet stove/soldering/water heater

Alumina ceramic components

Alumina ceramic components

High Temperature Resistant Al2O3 Ceramic Crucibles

99% Al2O3 Ceramic crucible for gold melting

High Purity Heat Resistant Alumina Ceramic Tube

Precision alumina ceramic tube

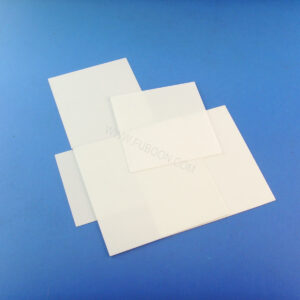

Al2O3 Ceramic Substrate

Al2O3 Ceramic Substrate for electronics

Alumina Ceramic Valve Disc parts

Alunima ceramic disc for faucet cartridge and valve .

Electrical ceramic insulators

ceramic insulators for heaters electrical ceramic insulators

Alumina Ceramic Bushing Sleeve Tubes

With hign wear resistance and favorable erosion resistance,the ceramic tube is widely used in the high corrosive and high-temperature environment like thermal power plants,mining,metallurgy,cement plants,etc.

Alumina Ceramic Industrial Nozzle

Ceramic nozzle for welding and sand blast