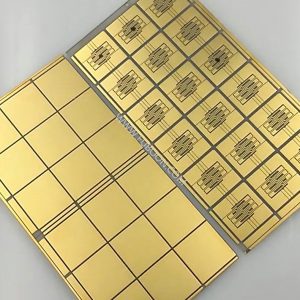

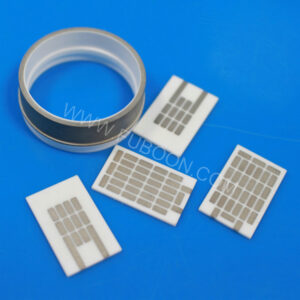

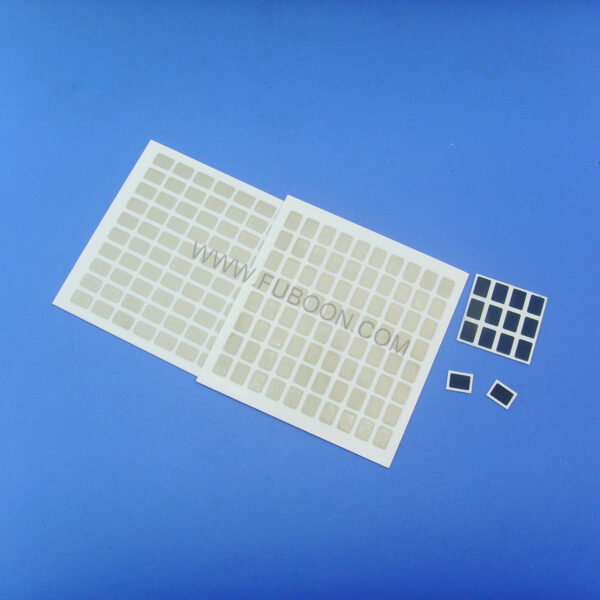

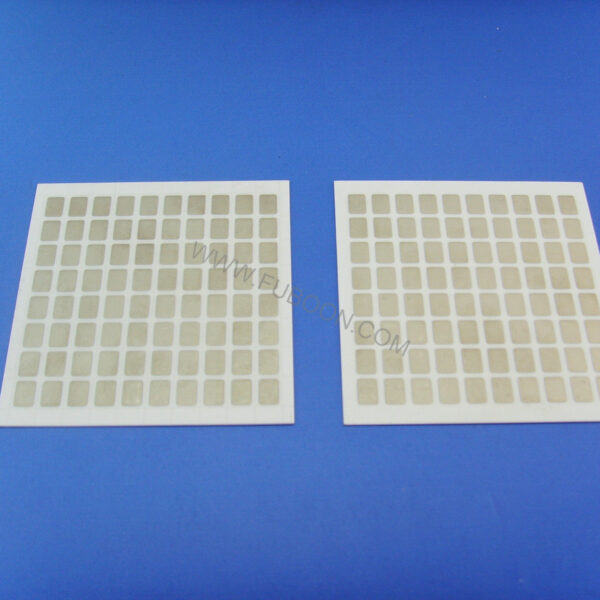

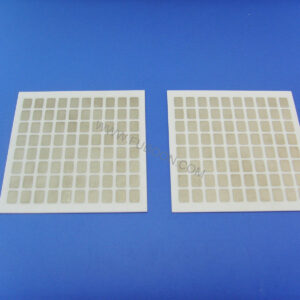

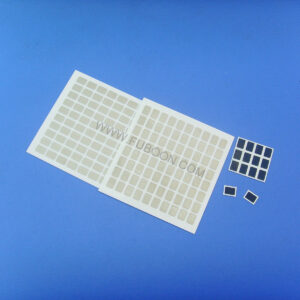

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

- Description

- Inquiry

Al2O3 alumina insulator ceramic heat sink substrate

Al2O3 alumina insulator ceramic heat sink substrate

Metallized ceramics for vacuum interrupters,metallized ceramics for electrical and electronic devices, ceramic brazed components, ceramic metallizing, welding ceramic part.

Provide solutions for high reliability vacuum-tight joints with extreme bond strength. Metallized ceramics are commonly used in many applications, for example in power electronics components placed under extreme load, electrical drive engineering and electrical engineering as well as in electronic components for computer technology.

We makes hermetic ceramic-to-metal joints possible with extremely high bond strengths exceeding 200 N/mm².

Applications:

1.Electrical transmission and distribution

2.Electronics industry

3.Textile machinery

4.Defense

5.Medical electronics

6.Automobile industry

7.Avionics

8.Solid Oxide Fuel Cells

9.White goods

10.High power/High temperature application

Property chart for metallization

No. | Item | Index |

1 | Thickness of metal layer

| Mo-Mn, 8μm Min |

Ni: 2μm Min | ||

2 | Bonding strength | >650N/cm2 |

3 | Solderability | Temperature for soldering tin: 235±5°C dip time lasts 5 second, fresh, glossy and connective solder covered on more than 95% area of bonding pad.

|

4 | Resistance of solderability

| Temperature for soldering tin: 260±5°C dip time lasts 20 seconds, fresh, glossy and connective solder covered on more than 95% area of bonding pad.

|

We can supply the products according to customer’s drawings, samples and performance requirement.

Related Products

High Temperature Resistance Alumina Metallized Ceramic Ring

High Temperature Resistance Alumina Metallized Ceramic Ring

Metallized Al2O3 Ceramics Substrate Ni/Au Plating

AlN Aluminum Nitride Ceramic Metallized DPC Substrate with Au/Cu Coating

Metallized AIN Aluminum Nitride Ceramics Substrate Ni/Au Plating

Metallized Ceramic Components for Kovar Brazing

Metallized Ceramic Vacuum Interrupters

Metallized Ceramics for Vacuum interrupters

Metallized Ceramic Alumina Insulator for Brazing

Metallized Alumina Ceramic Feedthrough Ceramic Vacuum Electrodes

Alumina Mo-Mn Metallization

Alumina Mo-Mn Metallization/Metallized Ceramic Tube For Vacuum Electron Device

Metallized Ceramic Housing for Power Semiconductors

Metallized Ceramic Housing for Power Semiconductors