Metallized Ceramic Housing for Power Semiconductors

Metallized Ceramic Housing for Power Semiconductors

- Description

- Inquiry

Metallized Ceramic Housing for Power Semiconductors

![]()

![]()

The description of

Metallized Ceramic Housing for Power Semiconductors

We have been supplying a variety of different ceramic grades with metallization, including 95% alumina, 99% alumina, zirconia, beryllia oxides. It makes us unable to meet the different need from different customers.

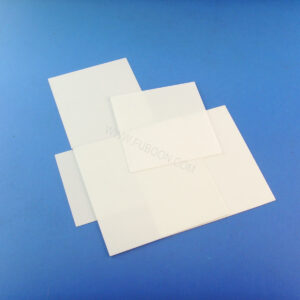

Metallized Ceramic Housing for Power Semiconductors

The metalized alumina ceramic housings we manufactured are famous for the excellent bonding strength, dense, non-porous ceramic body and vacuum-tight performance, good high-temperature characteristics, and low coefficient of expansion, and so on.

Jointing types:

1.Alumina ceramic base + Ag plating

2.Alumina ceramic base + Mo/Mn metallization

3.Alumina ceramic base + Mo/Mn metallization + Ni plating

4. Alumina ceramic base + Tungsten metalized + Au plating

Cosmetic quality:

1. The flatness of both end sides must be less than 0,01mm

2.No blister on nickel ( outer) plating at the temperature up to 1150°C

3.No any crack on the surface

4.No any dark spot ( impurities) on the external surface

5.With evenly glaze distribution

Application:

Diode, Gas triode, Vacuum thyristor, the X-ray tube, and so on.

Overview of Main Physical Properties:

1.Good electrical insulation

2.High mechanical strength

3.Excellent wear resistance

4.Excellent corrosion resistance

5.Low dielectric constant

Overview of Main Applications:

1.Pump seals and other components

2.Wear resistant inserts

3.Insulating washers or bushings

4.Semiconductor components

5.Aerospace components

6.Automotive sensors

7.Electrical or electronic insulators

Metallized Ceramic Housing for Power Semiconductors

Descriptions of Metallization Processing:

| Metallization Processing (See Process Description Below) | Outer Diameter and Inner Diameter Banding |

| Brush | |

| Screen Printing | |

| Spray | |

| Needle | |

| Base Metallization Materials | Moly Manganese |

| Tungsten Manganese | |

| Moly Tungsten Manganese | |

| Materials for Metallization | Aluminum Oxide |

| Beryllium Oxide (Restrictions Apply) | |

| Metallization Characteristics/Benefits | Low Temperature Firing |

| Universally Applicable | |

| Process Speed | |

| Uniform Coating, Thickness and Density | |

| No substrate deformation | |

| Metallization Equipment | Domestic Furnaces |

| Industry Focus | Department of Defense |

| Department of Energy | |

| Solar Product Manufacturing | |

| Aerospace | |

| Biomedical | |

| Communications | |

| Computer and Electronics | |

| Vacuum Electronics | |

| Medical | |

| Military | |

| Semiconductor | |

| Optical | |

| Intended Applications for Metallization Products | Traveling Wave Tubes |

| Vacuum Electronic Devices | |

| Medical Devices | |

| Photon Machines | |

| Neutron Generators | |

| X-Ray Tubes | |

| Klystrons | |

| High Vacuum Feed Through | |

| Relay Insulators | |

| E-Beam Technology |

Available Metallization&Plating Specifications:

| Available Ceramic Compositions | Al2O3 94%,97%,99.5% |

| Available Metallization Materials | Mo/Mn |

| Metallization Thickness | 25±10um |

| Available Plating Materials | Ni/Ag/Au |

| Plating Thickness | 2-10um |

Related Products

Ceramic Igniter for Wood Pellet Stove

Ceramic Igniter for wood pellet stove/soldering/water heater

Alumina resistor ceramic rod

Alumina resistor ceramic rod 3mm – 25mm

Ceramic valve ball and seat components

Ceramic valve components.Including valve ball(O-port and V-port),Seats and other parts for full-lined ceramic ball valve.

Al2O3 Ceramic Substrate

Al2O3 Ceramic Substrate for electronics

Alumina Ceramic Bushing Sleeve Tubes

With hign wear resistance and favorable erosion resistance,the ceramic tube is widely used in the high corrosive and high-temperature environment like thermal power plants,mining,metallurgy,cement plants,etc.

Alumina Ceramic Industrial Nozzle

Ceramic nozzle for welding and sand blast

High Temperature Resistant Al2O3 Ceramic Crucibles

99% Al2O3 Ceramic crucible for gold melting

Furnace Kiln High Temperature Resistant Alumina Ceramic Tube

High-temperature alumina ceramic tube

Electrical ceramic insulators

ceramic insulators for heaters electrical ceramic insulators

Alumina ceramic components

Alumina ceramic components