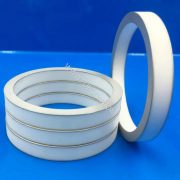

96% Al2O3 Alumina Metallized Ceramic Ring for Power Grid Tubes RF Windows

- Description

- Inquiry

96% Al2O3 Alumina Metallized Ceramic Ring for Power Grid Tubes RF Windows

Metallized Ceramic Ring Componenets:

FUBOON supplies precision metallized ceramic ring in aluminum oxide ceramics for the medical, and aerospace industries. Through spray, needle, and brush coatings or screen printing our capabilities allow us to metallized on flat, cylindrical, and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.In order to achieve the welding between ceramic and metal, the ceramic surface firmly adheres to a layer of the metal film, which is ceramic metallization.Refractory-metalized aluminum oxide ceramics widely use in power grid tubes, vacuum interrupters, and similar applications where metal to ceramic joints of exceptional strength and hermeticity is required.

Product Name | Metallized Alumina Ceramic Parts Insulator |

Material | 95%, 96%, 99% Alumina (AL2O3) |

Color | White+Metal |

Coaing Layer | Mo/Mn |

Coaing thickness | 8-30um |

Plated Layer | Ni,Cu,Au,Etc |

Plating thickness | 1-9um |

Specification

Special types are available according to customer’s drawings or samples

Characteristics:

Material Properties:

Main Features

• High hardness with low density

• Wear & abrasion resistant

• Resists strong acid and alkali attack at high temperatures

• Excellent electrical insulation properties

• High compressive strength

• High mechanical Strength

• Excellent refractory material

• Moderate thermal conductive and thermal expansion rates

• Resistant to thermal shock

• High dielectric strength

• Transparent to microwave radio frequencies

Related Products

Alumina ceramic components

Alumina ceramic components

99% Al2O3 mechanical Alumina oxide ceramic seal ring

99% Al2O3 mechanical Alumina oxide ceramic seal ring

Furnace Kiln High Temperature Resistant Alumina Ceramic Tube

High-temperature alumina ceramic tube

Ceramic valve ball and seat components

Ceramic valve components.Including valve ball(O-port and V-port),Seats and other parts for full-lined ceramic ball valve.

Alumina resistor ceramic rod

Alumina resistor ceramic rod 3mm – 25mm

Alumina ceramic screw

M2 M3 M4 M5 M6 alumina ceramic screw/ceramic nut

Ceramic Igniter for Wood Pellet Stove

Ceramic Igniter for wood pellet stove/soldering/water heater

Alumina Ceramic Valve Disc parts

Alunima ceramic disc for faucet cartridge and valve .

Alumina Ceramic Industrial Nozzle

Ceramic nozzle for welding and sand blast

High Purity Heat Resistant Alumina Ceramic Tube

Precision alumina ceramic tube