Metallized Ceramic Vacuum Interrupters

Metallized Ceramics for Vacuum interrupters

- Description

- Inquiry

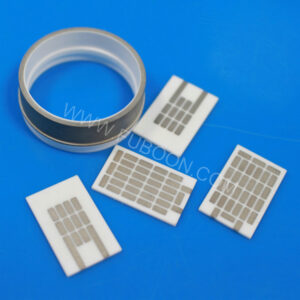

Metallized Ceramic Vacuum Interrupters

![]()

![]()

Specifications

Big Diametre Glazing & Metallized Ceramic Tubes

1.Good electrical insulation

2.Wear resistant

3.Corrosion resistant

Big Diametre Glazing&Metallized Ceramic Tubes for Vacuum Interrupters

High Alumina Metallized Ceramic Tube Insulator

Electrical Ceramic Insulator

Al2O3 Ceramic Insulator

Ceramic with metallization

Metallized Ceramic Vacuum Interrupters

FUBOON suppliers precision Big Diametre Glazing&Metallized Ceramic Tubes in alumium oxide ceramics for the military,medical and aerospace industries.Through spray,needle and brush coatings or screen printing our capabilities allow us to metallized on flat,cylindrical and complex ceramic bodies. Moly-Manganese is the typical base coat materials used for metallization.

Overview of Main Physical Properties:

1.Good electrical insulation

2.High mechanical strength

3.Excellent wear resistance

4.Excellent corrosion resistance

5.Low dielectric constant

1) High-intensity sealing, high air-tightness, high reliability, good heat resistance

2) Excellent insulation performance and high temperature resistance

3) Good mechanical , electrical and thermal conductivity

4) Great bonding strength

5) Widely used for all electric products and electric heating products1.Material: 96% Aluminia(AL2O3)

2.Coating Layer:Molybdenum-Mananese(Mo/Mn)

3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos.

. A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different

coefficient of thermal expansion.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.

The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Electronics industry

Textile machinery

Defense

Medical electronics

Automobile industry

Sealing

Solid Oxide Fuel Cells

High temperature application

metallized ceramics for vacuum interrupters,metallized ceramics for electrical and electronic devices, ceramic brazed components,ceramic metallizing, welding ceramic part.

Descriptions of Metallization Processing:

| Metallization Processing (See Process Description Below) | Outer Diameter and Inner Diameter Banding |

| Brush | |

| Screen Printing | |

| Spray | |

| Needle | |

| Base Metallization Materials | Moly Manganese |

| Tungsten Manganese | |

| Moly Tungsten Manganese | |

| Materials for Metallization | Aluminum Oxide |

| Beryllium Oxide (Restrictions Apply) | |

| Metallization Characteristics/Benefits | Low Temperature Firing |

| Universally Applicable | |

| Process Speed | |

| Uniform Coating, Thickness and Density | |

| No substrate deformation | |

| Metallization Equipment | Domestic Furnaces |

| Industry Focus | Department of Defense |

| Department of Energy | |

| Solar Product Manufacturing | |

| Aerospace | |

| Biomedical | |

| Communications | |

| Computer and Electronics | |

| Vacuum Electronics | |

| Medical | |

| Military | |

| Semiconductor | |

| Optical | |

| Intended Applications for Metallization Products | Traveling Wave Tubes |

| Vacuum Electronic Devices | |

| Medical Devices | |

| Photon Machines | |

| Neutron Generators | |

| X-Ray Tubes | |

| Klystrons | |

| High Vacuum Feed Through | |

| Relay Insulators | |

| E-Beam Technology |

Available Metallization&Plating Specifications:

| Available Ceramic Compositions | Al2O3 94%,97%,99.5% |

| Available Metallization Materials | Mo/Mn |

| Metallization Thickness | 25±10um |

| Available Plating Materials | Ni/Ag/Au |

| Plating Thickness | 2-10um |

Related Products

Electrical 99% Alumina Ceramic Metallized DBC Substrate

Ceramic substrates for LED

Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate

High Temperature Resistance Alumina Metallized Ceramic Ring

High Temperature Resistance Alumina Metallized Ceramic Ring

Insulating Metallized Ceramic Frame

Metallized Ceramic Components for Kovar Brazing

Al2O3 Alumina Metallized Ceramic Single Feedthroughs

Glazed Nickel Plating Al2O3 Alumina Metallized Ceramic Single Feedthroughs For Electrical Isolation

Metallized Ceramic Alumina Insulator for Brazing

Alumina Mo-Mn Metallization

Alumina Mo-Mn Metallization/Metallized Ceramic Tube For Vacuum Electron Device

High Voltage Alumina Metalized Ceramic Insulator

High Voltage Alumina Metalized Ceramic Insulator for X-ray Tube

Metallized Ceramic Housing for Power Semiconductors

Metallized Ceramic Housing for Power Semiconductors