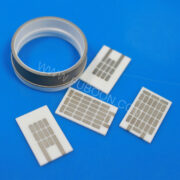

Al2O3 Alumina Metallized Ceramic Single Feedthroughs

Glazed Nickel Plating Al2O3 Alumina Metallized Ceramic Single Feedthroughs For Electrical Isolation

- Description

- Inquiry

Glazed Nickel Plating Al2O3 Alumina Metallized Ceramic Single Feedthroughs For Electrical Isolation

High Hermeticity Metallized Ceramic Bushing

Features:

1.Material: 96% Aluminia(AL2O3)

2.Coating Layer:Molybdenum-Mananese(Mo/Mn)

3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos.

A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering.

The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Electronics industry

Textile machinery

Defense

Medical electronics

Automobile industry

Sealing

Solid Oxide Fuel Cells

High temperature application

We can supply the products according to customer’s drawings, samples and performance requirement.

metallized ceramics for vacuum interrupters,metallized ceramics for electrical and electronic devices, ceramic brazed components, ceramic metallizing, welding ceramic part.

Overview of Main Physical Properties:

1.Good electrical insulation

2.High mechanical strength

3.Excellent wear resistance

4.Excellent corrosion resistance

5.Low dielectric constant

Overview of Main Applications:

1.Pump seals and other components

2.Wear resistant inserts

3.Insulating washers or bushings

4.Semiconductor components

5.Aerospace components

6.Automotive sensors

7.Electrical or electronic insulators

Related Products

Alumina Ceramic Bushing Sleeve Tubes

With hign wear resistance and favorable erosion resistance,the ceramic tube is widely used in the high corrosive and high-temperature environment like thermal power plants,mining,metallurgy,cement plants,etc.

Alumina Ceramic precision ball

Alumina Ceramic precision ball for bearing

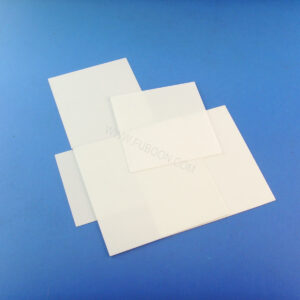

Al2O3 Ceramic Substrate

Al2O3 Ceramic Substrate for electronics

Alumina liner tube sleeve cylinder for pump

Alumina liner tube/sleeve/cylinder for pump

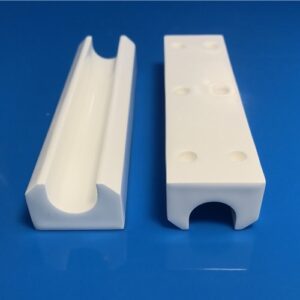

Alumina ceramic components

Alumina ceramic components

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector

99% Alumina ceramic OD300 Large diameter liner

99% Alumina ceramic OD300 Large diameter liner

High Purity Heat Resistant Alumina Ceramic Tube

Precision alumina ceramic tube

99% Al2O3 mechanical Alumina oxide ceramic seal ring

99% Al2O3 mechanical Alumina oxide ceramic seal ring

Ceramic valve ball and seat components

Ceramic valve components.Including valve ball(O-port and V-port),Seats and other parts for full-lined ceramic ball valve.