Metallized Ceramic Components for Kovar Brazing

- Description

- Inquiry

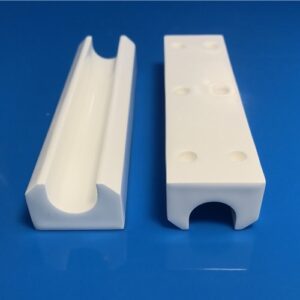

Metallized Ceramic Components

Material : 96.0% alumina or 99.5% high purity alumina with Metalization treatment

– Either Cold Isostatic Press or dry press formed bodies with secondary fine-machining

– High precision and good appearance after metalization

– Easy for brazing with Kovar alloy directly

– High bonding strength after brazing with kovar parts

– Good insulation, anti-magnetic, static electricity-free character for feedthrough use

– Excellent thermal shock resistance and good thermal stability after brazing

– Outstanding bending strength and toughness

– Anti corrosion & abrasion resistance in harsh working environments

– Professional ceramic R&D team is available for your requests of various metallized ceramic parts

Product Name | Custom Industrial Metallized Ceramic Components for Kovar Brazing with Tight Hermetic Sealing |

Compositions | 96.0% alumina or 99.5% high purity alumina (Al2O3) |

Metalization | Sintered with Molybdenum & Manganese (Mo+Mn), then Nickel plating |

Mo+Mn Layer | 25 +/-10μm in thickness |

Nickel Layer | 2 -10μm in thickness |

Material Density | 3.90 g/cm3 |

Tolerance | +/- 0.005mm |

Finishing | Ra 0.02 |

Max. Using Temperature | 1650 oC |

Using Fields | Feedthrough, Fuel cell, PVD or CVD machines, Power Staions, Semi conductors, Electronics Equipments, Aerospace |

Metallized Ceramic Components

Kovar Alloy Chemical Compositions Sheet | ||||

Elements | Symbol | YB/T 5231 | ASTM F15 | DIN 17745 |

4J29 | K94610 | 1.3981 | ||

Carbon | C | ≤0.03 | ≤0.04 | ≤0.05 |

Silicon | Si | ≤0.30 | ≤0.20 | ≤ 0.30 |

Manganese | Mn | ≤0.50 | ≤0.50 | ≤0.50 |

Phosphorus | P | ≤0.020 | – | – |

Sulphur | S | ≤0.020 | – | – |

Nickel | Ni | 28.5~29.5 | 29.0* | 28.0~30.0 |

Cobalt | Co | 16.8~17.8 | 17.0* | 16.0~18.0 |

Chromium | Cr | ≤0.20 | ≤0.20 | – |

Copper | Cu | ≤0.20 | ≤0.20 | – |

Molybdenum | Mo | ≤0.20 | ≤0.20 | – |

Aluminum | Al | – | ≤0.10 | – |

Magnesium | Mg | – | ≤0.10 | – |

Zirconium | Zr | – | ≤0.10 | – |

Titanium | Ti | – | ≤0.10 | – |

Iron | Fe | Balance | 53.0* | Rest |

*:norminal valves, they should be adjusted by the manufacturer so that the alloy meet the requirement for CTE in different temperature range | ||||

Related Products

Furnace Kiln High Temperature Resistant Alumina Ceramic Tube

High-temperature alumina ceramic tube

Alumina Ceramic precision ball

Alumina Ceramic precision ball for bearing

Alumina resistor ceramic rod

Alumina resistor ceramic rod 3mm – 25mm

Al2O3 Ceramic Steel Shaft

Alumina Al2O3 Ceramic Steel Shaft

Alumina liner tube sleeve cylinder for pump

Alumina liner tube/sleeve/cylinder for pump

99% Al2O3 mechanical Alumina oxide ceramic seal ring

99% Al2O3 mechanical Alumina oxide ceramic seal ring

Alumina Ceramic Laser Reflector

Alumina Ceramic Laser Reflector

Alumina ceramic screw

M2 M3 M4 M5 M6 alumina ceramic screw/ceramic nut

High Purity Heat Resistant Alumina Ceramic Tube

Precision alumina ceramic tube

Alumina Ceramic Industrial Nozzle

Ceramic nozzle for welding and sand blast