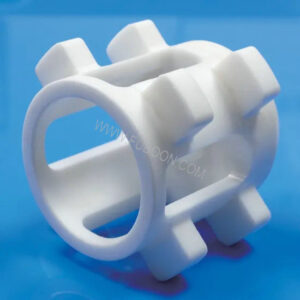

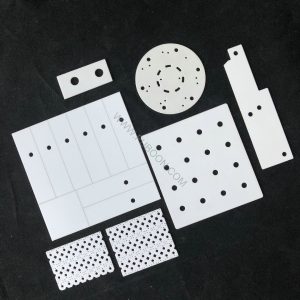

Alumina ceramic components

Alumina ceramic components

- Description

- Inquiry

Alumina ceramic components

Features of the ceramics parts:

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) High strength

6) Used in all electric products, electric heating products and wear resistant machinery parts.

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Alumina ceramic components

Wear ceramic parts

- Ceramic Nozzles

- Ceramic Sprayers Cyclones

- Homogenising devices

- Ceramic Linings

- Milling Systems

- Ceramic Thread guides

Precision components

- Ceramic Measuring Components

- Ceramic Control systems

- (Micro) dosing valves

- Electronics

- Components,

- Mechatronics

- Optical applications

Machine-construction

- Positioning

- Guide parts

- Coatings,

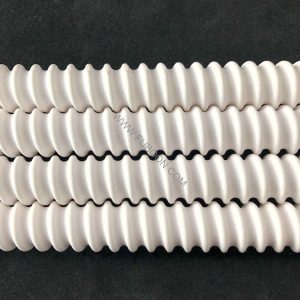

- Transport ceramic rollers

- Ceramic Dies

- Textile machine parts,

- Furnace parts

Rotating equipment

- Ceramic Sliding Bearings

- Ceramic Ball bearings

- Mechanical seals

- Ceramic Plungers

- Ceramic Valves / fittings,

- Dosing components

Cutting & moulding

- Ceramic knives

- Metal-forming tools

- Seaming rolls

- Ceramic Punches

- Drawing dies