– High Thermal Conductivity Substrates for LED & Power Electronics

– Substrates for Power Electronics

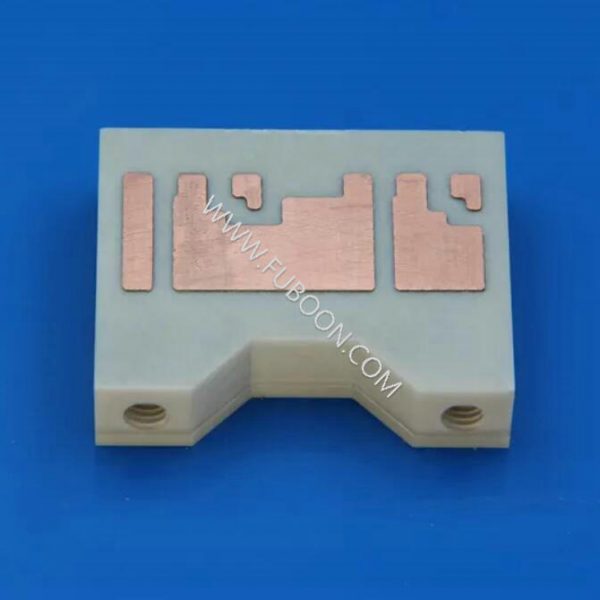

Aluminum Nitride Active Metal Brazed (AMB) Ceramic tructural Parts

AMB (Active Metal Brazing) is for joining ceramics that are not wetted by ‘conventional’ brazes.

Aluminium Nitride Material Properties | ||

Properties | FUB-AN170 | |

Color | Dark Gray | |

Main Content | 96%ALN | |

Bulk Density(g/cm3) | 3.335 | |

Water Absorption | 0.00 | |

Flexural Strength(MPa) | 382.70 | |

Dielectric Constant(1MHz) | 8.56 | |

Coefficient Linear Thermal Expansion | /℃ ,5℃/min, 20-300℃ | 2.805*10-6 |

Thermal Conductivity | 30 degree Celsius | >=170 |

Chemical Durability(mg/cm2) | 0.97 | |

Thermal Shocking Resistance | No cracks | |

Volume Resistivity(Ω .cm) | 20 degree Celsius | 1.4*1014 |

Dielectric Strength(KV/mm) | 18.45 | |

Surface roughness Ra(μm) | 0.3-0.5 | |

Camber(length ‰ ) | <=2‰ | |

Remark: The value is just for review, different using conditions will have a little difference. | ||

Aluminum Nitride Active Metal Brazed (AMB) Ceramic

Application

– RF / Microwave Components

– Laser Diode Sub-mounts

– High Thermal Conductivity Substrates for LED & Power Electronics

– Substrates for Power Electronics

– High Thermal Conductivity Substrates for LED & Power Electronics

– Substrates for Power Electronics

High-temperature alumina ceramic tube

Alumina Ceramic precision ball for bearing

Alumina liner tube/sleeve/cylinder for pump

99% Al2O3 mechanical Alumina oxide ceramic seal ring

Alumina Al2O3 Ceramic Steel Shaft

Precision alumina ceramic tube

Ceramic Igniter for wood pellet stove/soldering/water heater

Al2o3 ceramic shaft piston plunger

M2 M3 M4 M5 M6 alumina ceramic screw/ceramic nut

Alumina Ceramic Laser Reflector