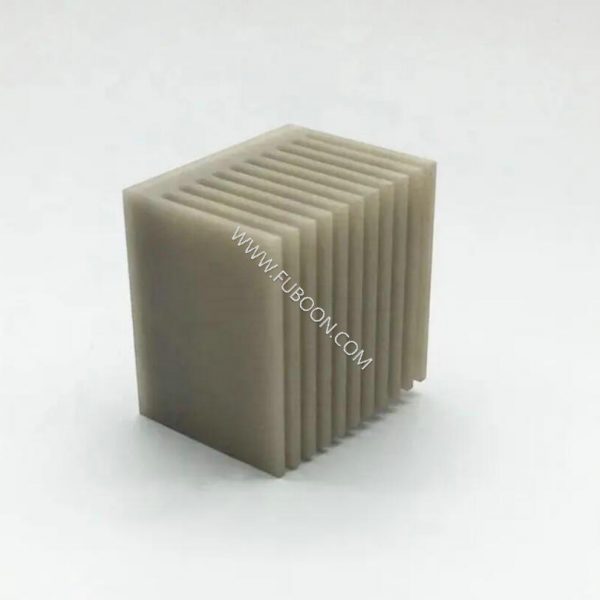

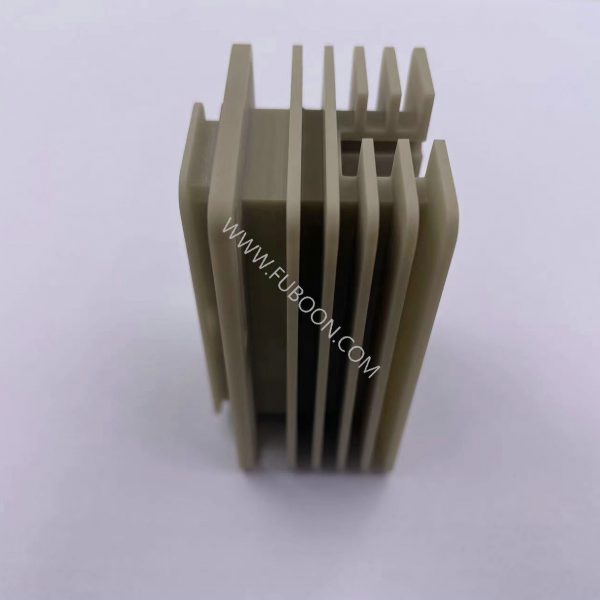

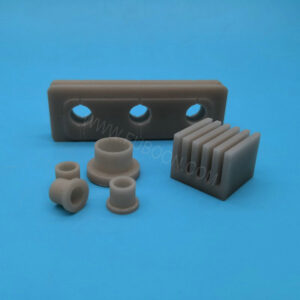

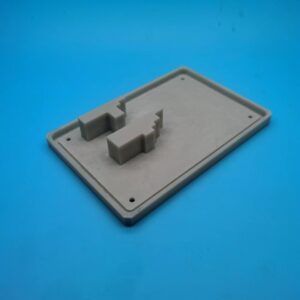

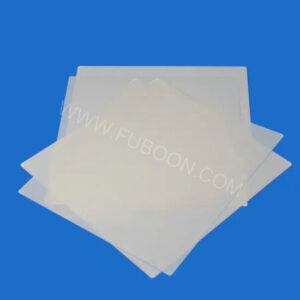

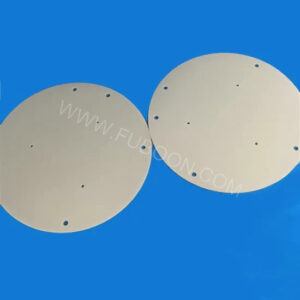

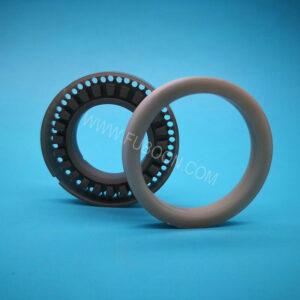

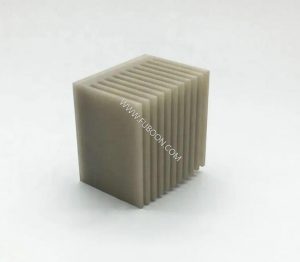

Ceramic AlN Aluminium Nitride Heat Spreaders Parts

- Description

- Inquiry

Ceramic AlN Aluminium Nitride Heat Spreaders Parts

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low

dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic,

high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is

widely used in communication components, high power led, power electronic devices and other

fields.Special spec products can be produced upon requests.

AlN Aluminium Nitride Heat Spreaders Parts

PRODUCT PERFORMANCE

– High thermal conductivity, high flexural strength, high temperature

– Good electrical insulation

– Low dielectric constant and loss

– Able to be laser drilled, metallized, plated and brazed

Product Features

1.Uniform microstructure

2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives

3.High electrical resistivity

4.Thermal expansion coefficient close to that of Silicon

5.Resistance to corrosion and erosion

6.Excellent thermal shock resistance

7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation

occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Aluminium Nitride Material Properties | ||||

Material | ALN | |||

Item No. | FUB-AN180 | FUB-AN200 | FUB-AN220 | |

Color | Gray | Gray | Beige | |

Main Content | 96%ALN | 96%ALN | 97%ALN | |

Main Characteristics | High Thermal Conductivity,Excellent Plasma Resistance | |||

Main Applications | Heat Dissipating Parts,Plasma Resistance Parts | |||

Bulk Density | 3.30 | 3.30 | 3.28 | |

Water Absorption | 0 | 0 | 0 | |

Vickers Hardness(Load 500g) | 10.0 | 9.5 | 9. | |

Flexural Strength | >=350 | >=325 | >=280 | |

Compressive Strength | 2500 | 2500 | – | |

Young’ Modulus of Elasticity | 320 | 320 | 320 | |

Poisson’s Ratio | 0.24 | 0.24 | 0.24 | |

Fracture Toughness | – | – | – | |

Coefficient Linear Thermal Expansion | 40-400degree | 4.8 | 4.6 | 4.5 |

Thermal Conductivity | 20degree | 180 | 200 | 220 |

Specific Heat | 0.74 | 0.74 | 0.76 | |

Thermal Shocking Resistance | – | – | – | |

Volume Resistivity | 20degree | >=10-14 | >=10-14 | >=10-13 |

Dielectric Strength | >=15 | >=15 | >=15 | |

Dielectric Constant | 1MHz | 9 | 8.8 | 8.6 |

Loss Tangent | *10-4 | 5 | 5 | 6 |