– High Thermal Conductivity Substrates for LED & Power Electronics

– Substrates for Power Electronics

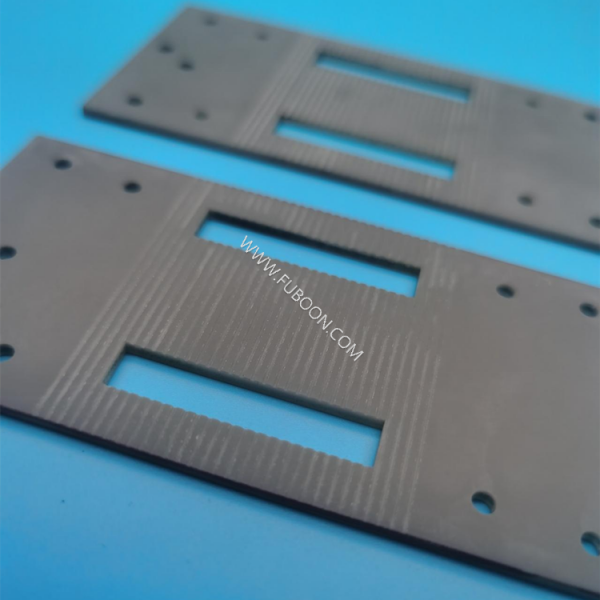

Hot Pressed Black Aluminum Nitride Ceramic Wafer

Hot pressed alumiunm nitride is used in applications requiring high electrical resistivity in additional to exceptional thermal conductivity.The application for hot pressed AlN typically involve rigorous or abrasive environments and high-tempreature thermal cycling.

Property | Units | Value |

Flexural Strength, MOR (20 °C) | MPa | 300-460 |

Fracture Toughness | MPa m1/2 | 2.75-6.0 |

Thermal Conductivity (20 °C) | W/m K | 80-140 |

Coefficient of Thermal Expansion | 1 x 10-6/°C | 3.3-5.5 |

Maximum Use Temperature | °C | 800 |

Dielectric Strength (6.35mm) | ac-kV/mm | 16.0-19.7 |

Dielectric Loss | 1MHz, 25 °C | 1 x 10-4 to 5 x 10-4 |

Volume Resistivity (25°C) | Ω-cm | 1013 to 1014 |

Application

– RF / Microwave Components

– Laser Diode Sub-mounts

– High Thermal Conductivity Substrates for LED & Power Electronics

– Substrates for Power Electronics

– High Thermal Conductivity Substrates for LED & Power Electronics

– Substrates for Power Electronics

Product Features

1.Uniform microstructure

2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives

3.High electrical resistivity

4.Thermal expansion coefficient close to that of Silicon

5.Resistance to corrosion and erosion

6.Excellent thermal shock resistance

AlN ceramic aluminum nitride part high thermal conductivity