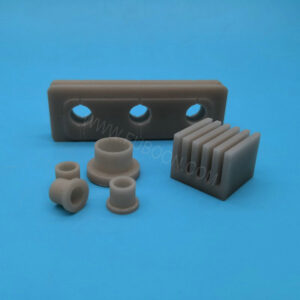

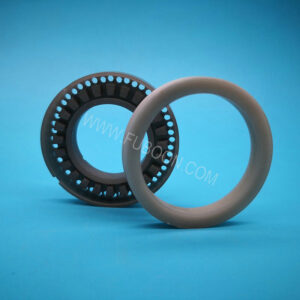

Heat Dissipation Structure Aluminum Nitride Ceramic Components

- Description

- Inquiry

Heat Dissipation Structure Aluminum Nitride Ceramic Components

With highly thermal conductivity ceramic heat dissipation components made from aluminum nitride for thermal management of high-power electronics, photovoltaic, automotive, LED and other applications.

About Aluminum Nitride Ceramics

Aluminum Nitride (AlN) Ceramics is an excellent ceramic material to use if high thermal conductivity and electrical insulation properties are required, making it an ideal material for use in thermal management and electrical applications.

Aluminum Nitride Ceramic has a coefficient of thermal expansion and electrical insulation properties that closely matches that of Silicon wafer material, making it an useful material for electronics applications where high temperatures and heat dissipation is often a problem.

Properties of Aluminum Nitride Ceramics

High thermal conductivity

Low coefficient of thermal expansion

Good electrical insulation and resistivity

Low dielectric constant

High mechanical strength under compression load

Corrosion resistant (gas)

Good thermal shock resistance

Applications of Aluminum Nitride Ceramics

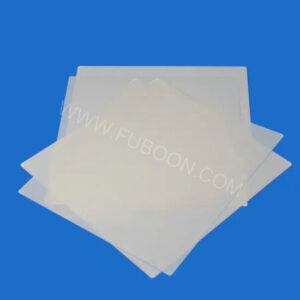

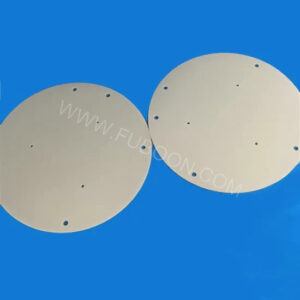

- Heat sinks & heat spreaders

- Electrical insulators for lasers

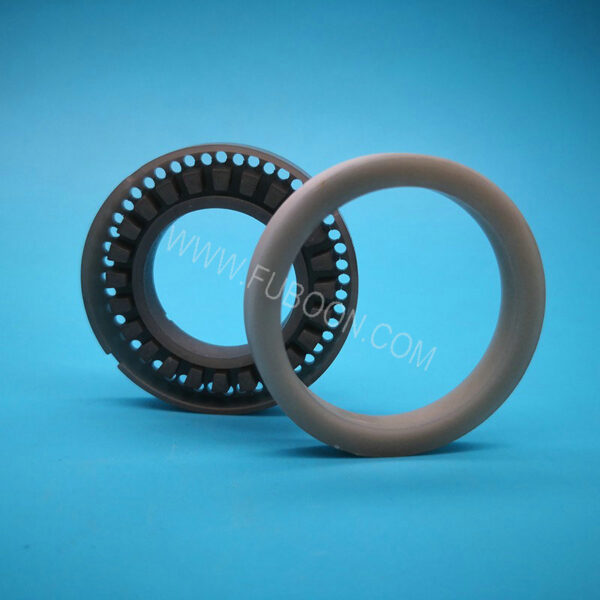

- Chucks, clamp rings for semiconductor processing equipment

- Electrical insulators

- Silicon wafer handling and processing

- Substrates & insulators for microelectronic devices & opto electronic devices

- Substrates for electronic packages

- Chip carriers for sensors and detectors

- Chiplets

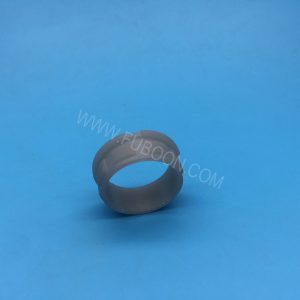

- Collets

- Laser heat management components

- Molten metal fixtures

- Packages for microwave devices

Heat Dissipation Structure Aluminum Nitride Ceramic Components

Properties | Units | Value |

Color | Grey | |

Mechanical Properties | ||

Density | g/cm3 | 3.30 |

Modulus of Elasticity | GPa | 310 |

Fracture toughness | Mpa x m^1/2 | 3.5 |

Poissons Ratio | 0.25 | |

Compressive Strength | MPa | 2100 |

Flexural Strength | MPa | 335 |

Hardness (Knoop 100 g) | Kg/mm2 | 1170 |

Hardness (Vickers) | GPa | 11 |

Thermal Properties | ||

Maximum Temperature | ||

Oxidizing | °C | 700 |

Inert | °C | 1300 |

Thermal Conductivity | ||

@ 25°C | W/mK | 180 |

@ 300°C | W/mK | 130 |

Specific Heat | J/kg.K | 750 |

Thermal Shock Resistance ΔT | °C | 400 |

Coefficient of Expansion | ||

CTE 25°C ➞ 100°C | 10^-6/°C | 3.6 |

CTE 25°C ➞ 300°C | 10^-6/°C | 4.6 |

CTE 25°C ➞ 500°C | 10^-6/°C | 5.2 |

CTE 25°C ➞ 1000°C | 10^-6/°C | 5.6 |

Electrical Properties | ||

Dielectric Constant | 1 MHz | 8.6 |

Loss Tangent | 1 MHz | 5×10^-4 |

Dielectric Strength | kV/mm | >15 |

Volume Resistivity | ||

25°C | Ω cm | >10^13 |

300°C | Ω cm | 10^9 |

500°C | Ω cm | 10^7 |