Al2O3 Alumina Ceramic Resistor Core

- Description

- Inquiry

Al2O3 Alumina Ceramic Resistor Core

Although it is an excellent electrical insulator, ceramic is also an excellent conductor of heat. This property of ceramic allows the cores of these resistors to withstand the passage of low to moderate electrical current without overheating or damage.

Al2O3 Alumina Ceramic Resistor Core are manufactured from a sintered body of ceramic material, with conductive particles distributed throughout the matrix, to produce a resistor that is 100% active and non-inductive. Ceramic resistors are chemically inert.

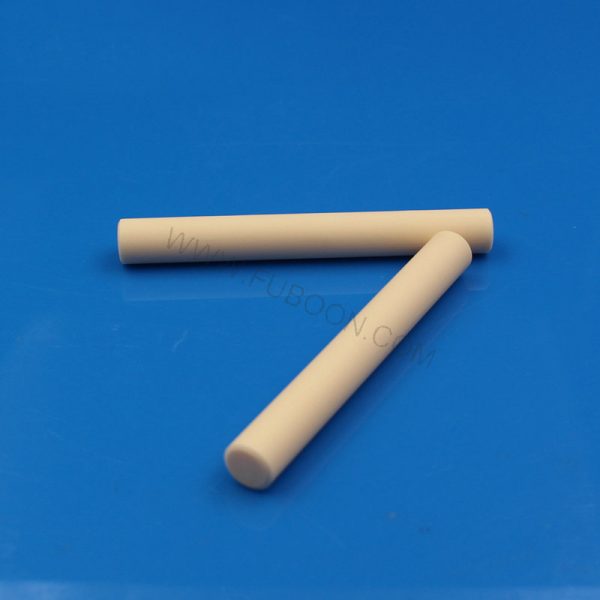

Ceramic is a common internal component in many types of resistors. In carbon film or resistive wire resistors, the resistive material is bonded to the outside of a ceramic core, usually cylindrical in shape. These cores provide a non-conductive base that holds the conductive elements of the resistor in place and gives the overall shape and size of the resistor.

Alumina ceramic resistor core is widely used in metallic oxide, carbon membrane, and wire-wound resistor for its following advantages.

▼ Applications

True ceramic resistors are widely used in many different types of electronic circuits and devices. Although these types of resistors can withstand very high operating temperatures, they also generate significant amounts of electrical noise. For this reason, ceramic resistors are rarely used in sensitive radio receivers or other devices that are particularly susceptible to interference.

• High voltage devider.

• Impulse high voltage resistor.

• High voltage high frequency resistor.

• Tubular non-inductive high voltage resistor.

• Ultra precision high power high voltage resistor.

Al2O3 Alumina Ceramic Resistor Core

A resistor is an electronic component of an electronic circuit that provides a specific resistance to current. Ceramic resistors can be divided into many different classes. These classes often depend on who is describing the resistor. To the layman or electrician, a ceramic resistor is usually a ceramic coated resistor. On the other hand, engineers and technicians define a ceramic resistor as one that uses ceramic to control the resistance value of the resistor.

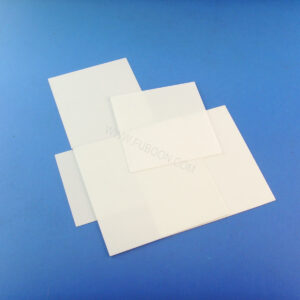

Due to its insulating and thermal properties, ceramics are used for external insulation and provide increased thermal durability for certain types of resistors. The most common are resistors that are manufactured by spinning a resistance wire around a ceramic core and then encasing it in a block or cylinder of ceramic material. The combination of external ceramic with metal and internal ceramic allows this type of resistor to withstand very high temperatures without damage.

On the other hand, a higher proportion of ceramic material will mean a higher resistive value of the resistor. Once the right proportions have been established, the mixture is compressed to shape and then fired in the furnace to fix the ceramic. It is common for these types of resistors to have an outer jacket of pure ceramic material to act as an external insulator.