Bulletproof ceramic materials

01The principle of Bulletproof with ceramic materials

The basic principle of armor protection is to dissipate the energy of a projectile, slow it down and render it harmless. Whereas most conventional engineering materials, such as metals, absorb energy through plastic deformation of the structure, ceramics absorb energy through micro-fracturing processes.

Bulletproof ceramic energy absorption process can be roughly divided into 3 stages:

(1) initial impact stage: the projectile impact ceramic surface, so that the warhead blunt, in the ceramic surface crushed to form a fine and hard fragmentation area in the process of energy absorption;

(2) Erosion phase: the blunted projectile continues to erode the fragmentation zone, forming a continuous layer of ceramic fragments;

(3) Deformation, cracking and fracture phase: finally, tensile stresses in the ceramic cause the ceramic to fragment, followed by deformation of the backing plate, with all the remaining energy being absorbed by the deformation of the backing plate material. During the impact of the projectile on the ceramic, both the projectile and the ceramic are damaged.

02Bulletproof ceramics on the material performance requirements

Because of the brittleness of the ceramic itself, its impact by the projectile fracture rather than plastic deformation. Under tensile loading, fracture first occurs at non-homogeneous places such as pores and grain boundaries. Therefore, in order to minimize microscopic stress concentrations, armour ceramics should be of high quality with low porosity (up to 99% of the theoretical density value) and fine grain structure.

03 The most commonly used bulletproof ceramic materials

Since the 21st century, the rapid development of bulletproof ceramics, more types, including alumina, silicon carbide, boron carbide, silicon nitride, titanium boride, etc., of which alumina ceramics (Al₂O₃), silicon carbide ceramics (SiC), boron carbide ceramics (B4C) is the most widely used.

Alumina ceramics have the highest density, but the hardness is relatively low, the processing threshold is low, the price is low, according to the purity is divided into 85/90/95/99 alumina ceramics, the corresponding hardness and price also increases in turn.

Comparison of the performance of different bulletproof ceramic materials

Silicon carbide ceramic density is relatively low, high hardness, belongs to the cost-effective structural ceramics, and therefore is currently the most widely used domestic bulletproof ceramics.

Boron carbide ceramics in these ceramics in the lowest density, the highest hardness, but at the same time its processing requirements are also very high, need high temperature and high pressure sintering, and thus the cost is also the highest of these three kinds of ceramics.

Comparison of the three more common bulletproof ceramic materials, alumina bulletproof ceramics cost the lowest but bulletproof performance is far worse than silicon carbide and boron carbide, so the current domestic production units on bulletproof ceramics silicon carbide and boron carbide bulletproof mostly, while alumina ceramics are rare. But single-crystal alumina can be used to prepare transparent ceramics, is widely used as a light function of transparent materials, in the soldier bulletproof mask, missile detection windows, vehicle observation windows, submarine periscopes and other military equipment to be applied.

04Two of the most popular Bulletproof ceramic materials

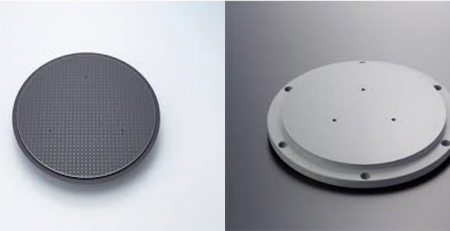

Silicon carbide Bulletproof ceramics

Silicon carbide covalent bond is extremely strong, at high temperatures still have high strength bonding, this structural feature gives the silicon carbide ceramics excellent strength, high hardness, wear resistance, corrosion resistance, high thermal conductivity, good thermal shock resistance and other properties; at the same time the silicon carbide ceramics are moderately priced, cost-effective, and one of the most potential for development of high-performance armor protection materials.

Silicon carbide ceramics in the field of armor protection has a broad space for development, in the field of warfighter equipment and special vehicles and other applications tend to be diversified. As protective armor materials, taking into account the cost and special applications and other factors, usually small rows of ceramic panels and composite back plate bonded into a ceramic composite target plate, in order to overcome the failure of ceramic due to tensile stress, and to ensure that the projectile penetration only crushed a single piece of the armor without destroying the whole.

Boron Carbide Bulletproof Ceramics

Boron carbide is currently known materials in the hardness second only to diamond and cubic boron nitride super-hard materials, hardness up to 3000kg/mm²; low density, only 2.52g/cm³, 1/3 of the steel; high modulus of elasticity, 450GPa; high melting point of about 2447 ℃; its coefficient of thermal expansion is low, high thermal conductivity. In addition, boron carbide has good chemical stability, acid and alkali corrosion resistance, at room temperature does not react with acid and alkali and most of the inorganic compounds and liquids, only in the hydrofluoric acid – sulfuric acid, hydrofluoric acid – nitric acid mixture of slow corrosion; and most of the molten metal is not wetting, does not occur. Boron carbide also has a very good ability to absorb neutrons, which is not available in other ceramic materials.B4C has the lowest density of several commonly used armor ceramics, coupled with a high modulus of elasticity, making it a good choice of materials for military armor and space.The main problems of B4C are expensive (about 10 times more expensive than alumina), brittle, which limits its wide use as a single-phase protective armor. The main problems with B4C are that it is expensive (about 10 times more expensive than aluminum oxide) and brittle, limiting its widespread use as single-phase protective armor.

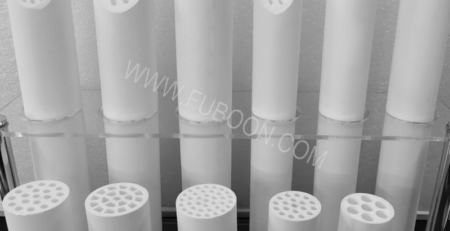

05 Preparation method of bulletproof ceramics

From the characteristics of the preparation process of ceramic materials can be seen, the current process development is more mature reaction sintering, pressureless sintering and liquid phase sintering, these three kinds of sintering method of production costs are lower, the preparation process is simpler, and the possibility of realizing mass production is higher. Hot pressure sintering and hot isostatic pressure sintering will be relatively limited by the size of the product, with higher production cost and lower maturity. Ultra-high-pressure sintering, microwave sintering, discharge plasma sintering and plasma beam melting method have the lowest maturity, and are relatively novel preparation means, but the requirements for technology and equipment are high, the production costs need to be invested are high, and the feasibility of realizing batch production is low, and they are often used in the stage of experimental exploration, which has little significance for practical application and is more difficult to realize industrialization.

06 Upgrading Bulletproof Ceramics

Although the bulletproof potential of silicon carbide and boron carbide is very large, the problem of poor fracture toughness and brittleness of single-phase ceramics cannot be ignored. And the development of modern science and technology on the functionality of bulletproof ceramics and economic requirements: multi-functional, high performance, lightweight, low cost and safety. Therefore, experts and scholars in recent years hope that through the micro-regulation, including multiple ceramic system composite, functional gradient ceramics, layered structure design, etc. to achieve ceramic toughness, lightweight and economical, and such armor relative to today’s armor light weight, and better improve the mobility of combat units.

Functional gradient ceramics that is through the micro-design component material properties are regular changes. For example, titanium boride and titanium metal, as well as alumina, silicon carbide, boron carbide, silicon nitride and aluminum metal metal and other metal / ceramic composite systems, performance along the thickness of the position of the gradient, that is, the preparation of the transition from high hardness to high toughness bulletproof ceramics.

Nano-complex phase ceramics is the sub-micron or nano-scale dispersed particles added to the matrix ceramics constitute the complex phase ceramics. Such as SiC-Si3N4 an Al2O3, B4C-SiC, etc., the hardness, toughness and strength of ceramics have been improved. It is reported that Western countries are studying the sintering of nanoscale powders to prepare ceramics with grain sizes of tens of nanometers, to achieve material toughness, bulletproof ceramics are expected to achieve a big breakthrough in this regard.

07 Summarize

Whether it is a single-phase ceramics or complex ceramics, the best bulletproof ceramic materials are still inseparable from the two materials of silicon carbide and boron carbide. Especially boron carbide materials, with the development of sintering technology, boron carbide ceramic excellence is more and more prominent, in the field of bulletproof applications will be further developed.