Aluminium Nitride for semiconductor industry

Aluminium nitride (AlN) with high strength, high volume resistivity, high insulation voltage, thermal expansion coefficient, and silicon match well, etc., not only used as structural ceramics sintering additives or reinforcing phase, especially in the field of ceramic electronic substrate and encapsulation materials in recent years, its performance is far more than alumina.

Aluminium nitride materials in the field of electronics and electric power, locomotives, aviation and aerospace, national defence and military industry, communications and many industrial areas have broad application prospects and a wide range of potential markets. Higher-end applications have become hot with the development of aluminium nitride crystal materials. Among them, the application of aluminium nitride in the semiconductor field has been attracting much attention.

Aluminium Nitride for semiconductor industry

Performance Characteristics of Aluminium Nitride Materials

Aluminium nitride (AlN) is a covalently bonded compound with a hexagonal fibrillated zincite structure and a lattice parameter of a = 3.114 and c = 4.986. Pure aluminium nitride is bluish-white in colour, and aluminium nitride behaves in the normal state usually in a grey or off-white colour. As a material with great potential, aluminium nitride possesses these performance characteristics:

① Thermal properties

The theoretical thermal conductivity of AlN is 320W/m-K, and the thermal conductivity of the actual prepared polycrystalline AlN is generally 100~260W/m-K. The room temperature thermal conductivity is 10~15 times of that of Al2O3, which is close to that of BeO (the theoretical thermal conductivity is 350W/m-K), and the thermal conductivity is better than that of beryllium oxide when the temperature is higher than 200°C. In the range of 25~400°C, the pure AIN has a thermal expansion coefficient of 4.4×10-6K-1, which is similar to that of silicon (3.4×10-6K-1).

② Electrical Properties

The room temperature electronegativity of pure AIN is more than 1014Ω-cm, which is a good insulating material; the dielectric constant is about 8.0 (1MHz), which is comparable to that of Al2O3; the dielectric loss is 10-4 (1MHz), and the insulating withstand voltage is 14KV-mm-1, and it has a high electromechanical coupling coefficient (0.8%), piezoelectricity and pro-negativity.

③ Mechanical properties

Room temperature, dense AIN ceramic Vickers hardness of 12GPa, Mohs hardness 7 ~ 8, Young’s modulus of 308GPa, flexural strength of up to 350MPa, strength with the rise in temperature and the decline is relatively slow, 1300 ℃ high-temperature strength than the room temperature strength of about 20% lower, while the hot pressing Si3N4, Al2O3 generally to reduce 50%.

④ Chemical properties

AIN has excellent high-temperature corrosion resistance, not infiltrated by aluminium, copper, silver, lead, nickel and many other metals, but also in certain molten salts, such as gallium arsenide in the molten salt of the stability of the existence of the AIN; AIN has a strong hygroscopicity, and is very easy to react with the water vapour in the air; in the air, the initial oxidation of the AIN temperature of 700 ~ 800 ℃. At atmospheric pressure, AIN does not melt, but undergoes thermal decomposition at 2260-2500℃.

Application of aluminium nitride in semiconductor field

① Substrate materials and packaging materials

With the booming development of microelectronics and semiconductor technology, the current power semiconductor devices need to have both high voltage, high current, high power density, small size and other characteristics, the electronic substrate heat flow density has increased dramatically, to maintain a stable operating environment within the device has become a key concern of the technical issues. For this reason, the substrate materials in power integrated circuits must have both good mechanical reliability and high thermal conductivity.

Aluminium Nitride for semiconductor industry

At present, the packaging substrate materials are mainly used in alumina ceramics or polymer materials, but with the increasingly stringent requirements for the carrier substrate of electronic parts, their thermal conductivity does not meet the needs of the industry, and AlN ceramics are considered to be a new generation of thermal dissipation substrate and the ideal for the encapsulation of electronic devices due to its high thermal conductivity, the coefficient of thermal expansion is close to the characteristics of silicon, high mechanical strength, chemical stability and environmental protection non-toxicity Material.

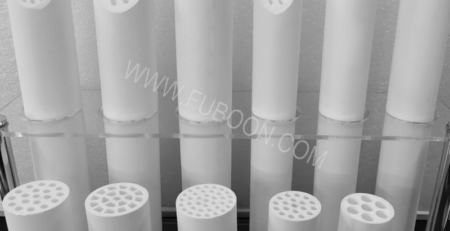

Compared with Al2O3 ceramic substrate and Si3N4 ceramic substrate, AlN ceramic substrate has these advantages: the use of AlN ceramic substrate as a carrier for the chip, the chip can be separated from the module heat dissipation substrate, the middle of the substrate of AlN ceramic layer can effectively improve the module’s insulation ability (ceramic layer insulation voltage > 2.5KV), and aluminium nitride ceramic substrate has good thermal conductivity, thermal conductivity In addition, AlN ceramic substrate expansion coefficient is similar to silicon, will not cause stress damage to the chip, aluminium nitride ceramic substrate peeling resistance> 20N/mm2, has excellent mechanical properties, corrosion resistance, not easy to deformation, can be used in a wide temperature range.

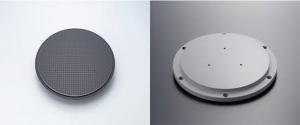

② Wafer processing with electrostatic suction cups

Modern semiconductor manufacturing process in the processing of wafers with a number of procedures, wafers need to be transmitted back and forth between the hundreds of process equipment, so there is a need for a device to clamp the wafers. Electrostatic suction cups can be fixed by electrostatic adsorption to the wafer, adsorption force is uniform and stable, the wafer will not warp and deform to ensure that the wafer processing accuracy and cleanliness. At present, the common electrostatic suction cup technology is mainly based on alumina ceramics or aluminium nitride ceramics as the main material. For ordinary silicon wafer processing, high-purity alumina or sapphire can meet the requirements, but if used in the processing of silicon carbide wafers, thermal conductivity is insufficient, must use aluminium nitride to meet the requirements.

Aluminium Nitride for semiconductor industry

The advantages of aluminium nitride ceramic electrostatic suction cups are: can control its volume resistivity, get a wide range of temperature range and full adsorption, electrostatic suction cups can be through the high degree of freedom of the heater design can achieve a good temperature uniformity; aluminium nitride through the one-piece co-firing type, there will be no deterioration of the electrode caused by the time change, the maximum to protect the product quality; in the plasma-halogen vacuum atmosphere environment to be able to The aluminium nitride can be operated under plasma halogen vacuum atmosphere to withstand the most demanding process environment of semiconductors and microelectronics, and it can also provide stable adsorption force and temperature control. It is heard that the application of aluminium nitride in the field of semiconductors in foreign countries has become the main market for aluminium nitride ceramics, the highest end of the electrostatic suction cups can even be sold to hundreds of thousands of yuan to millions of yuan, very “gold”.

③ substrate materials

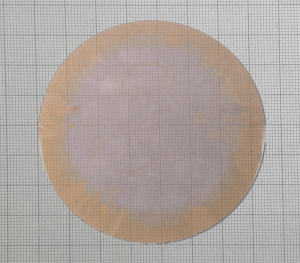

AlN crystal is GaN, AlGaN and AlN epitaxial material ideal substrate. Compared with sapphire or SiC substrate, AlN is more thermally and chemically compatible with GaN, and the stress between the substrate and the epitaxial layer is smaller. Therefore, AlN crystals, when used as GaN epitaxial substrates, can significantly reduce the defect density in the device, improve the performance of the device, and have good application prospects in the preparation of high-temperature, high-frequency, high-power electronic devices.

Aluminium Nitride for semiconductor industry

In addition, using AlN crystals as the substrate for AlGaN epitaxial materials with high aluminium (Al) composition can also effectively reduce the defect density in the nitride epitaxial layer, greatly improving the performance and service life of nitride semiconductor devices. High-quality day-blind detectors based on AlGaN have been successfully applied.

④ Thin film materials

Due to the wide band gap and strong polarisation of AlN, with a forbidden band width of 6.2eV, the aluminium nitride thin film materials prepared therefrom have many excellent physicochemical properties, such as high breakdown field strength, high thermal conductivity, high electrical resistivity, high chemical and thermal stability as well as good optical and mechanical properties, and are widely used as isolation media and insulating materials in the packaging of electronic devices and integrated circuits.

High-quality AlN film also has a very high ultrasonic transmission speed, small acoustic loss, considerable piezoelectric coupling constant, and Si, GaAs similar to the coefficient of thermal expansion, etc., unique properties make it in the mechanical, microelectronics, optics, as well as electronic components, surface-wave acoustic devices, manufacturing and high-frequency broadband communications and other fields have a broad range of applications.

Aluminium Nitride for semiconductor industry

At present, the preparation of aluminium nitride film is still in the stage of complex equipment, expensive and difficult to commercialise, and the method used to prepare the film usually requires the substrate to be heated to a higher temperature. The current low-temperature preparation of aluminium nitride thin films is still immature and imperfect. The development of integrated optical devices, on the other hand, requires film preparation at lower temperatures to avoid thermal damage to the substrate material. There is still a lot of work to be done to improve the preparation method of aluminium nitride films to obtain denser, more uniform, higher purity and lower cost aluminium nitride films at lower temperatures and simpler process conditions.

Aluminium Nitride for semiconductor industry