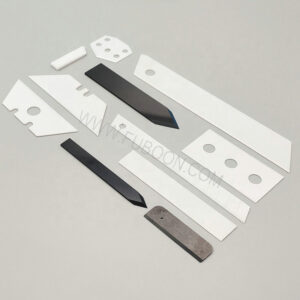

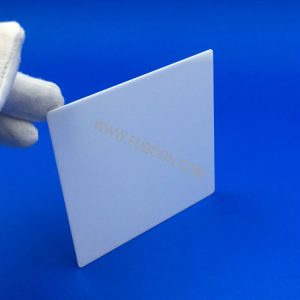

ZRO2 Zirconia Ceramic Sheet Substrate

- Description

- Inquiry

ZRO2 Zirconia Ceramic Sheet Substrate

The specification of ceramic parts

| Material option | Zirconia (ZrO2), Alumina(Al2O3), Silicon carbide(SiO2), Silicon nitride(Si3N4) |

| Forming methods | Dry pressed, Ceramic injection molding, Hot pressed, ISO pressed |

| Specification | OD can be from 1 to 50mm, length can be from 10mm to 800mm |

| Precision processing | CNC machining, Precision grinding, Polishing, Lapping, |

| Tolerance | The tolerance of OD and ID can be 0.001mm, the tolerance of length can be 0.001mm |

| Key parameters | Roughness to be 0.02mm, Parallelism to be 0.001mm |

| Surface quality | Free of cracks, foreign contamination, mirror surface better than Ra0.1 |

conductivity (heat insulation), generally no insulation and high temperature resistance

– – 95%–99.99% Alumina (Al2O3)

– – Silicon Carbide · Silicon Nitride

– – TTZ: Magnesia partially stabilized Zirconia (ZrO2)

– – YTZP: Yttria partially stabilized Zirconia (ZrO2)

– – ZDY: Yttria fully stabilized Zirconia (ZrO2)

* High thermal expansion (α=11 x 10-6/K, similar to some types of steel)

* Excellent thermal insulation/low thermal conductivity (2.5 to 3 W/mK)

* Very high resistance to crack propagation, high fracture toughness (6.5 to 8 MPam1/2)

* Ability to conduct oxygen ions (used for the measurement of oxygen partial pressures in lambda probes)

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

ZRO2 Zirconia Ceramic Sheet Substrate

Our capability and strength

We have in-housing comprehensive manufacturing types of equipment, including forming, sintering,

CNC machining, precision grinding, laser cutting, and so on, it helps us to control the quality very well.

Also, it greatly benefits cost control.