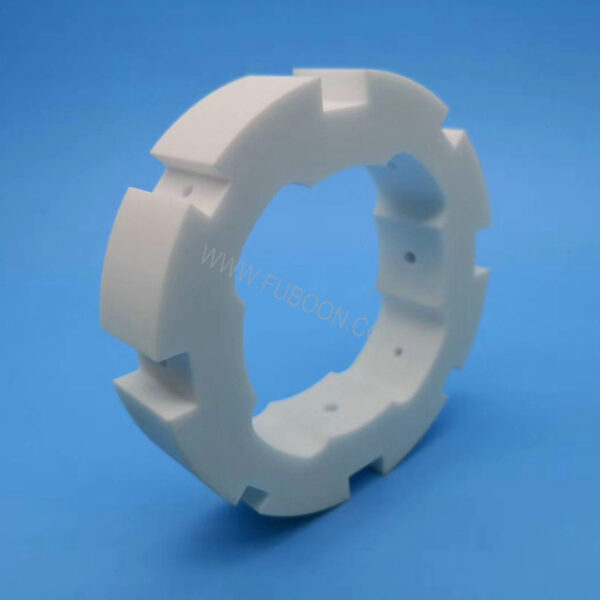

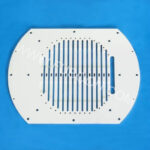

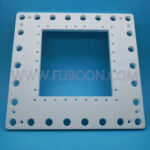

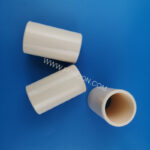

Zirconia ceramic Machinery components

Customized components as drawing and technicial requirement

- Description

- Inquiry

Zirconia ceramic Machinery components

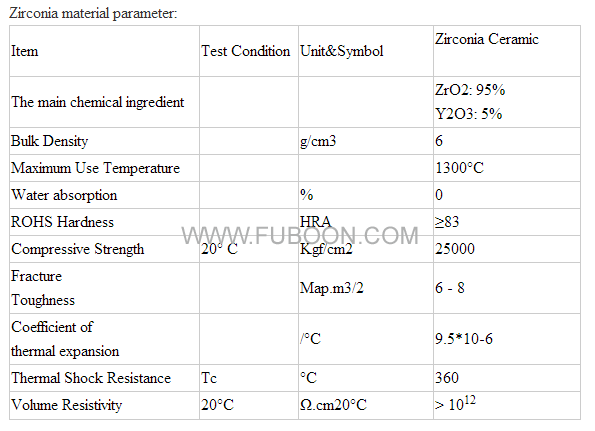

Zirconium oxide ceramics are white, yellow or gray when containing impurities, and generally contain HfO2, which is not easily separated. Pure ZrO2 has three crystal states under normal pressure. The production of zirconia ceramics requires the preparation of high-purity, good dispersion properties, ultra-fine particles, narrow particle size distribution, zirconia ultrafine powder preparation methods, zirconia purification mainly chlorination and thermal decomposition, alkali metal Oxidative decomposition method, lime melting method, plasma arc method, precipitation method, colloid method, hydrolysis method, spray pyrolysis etc.

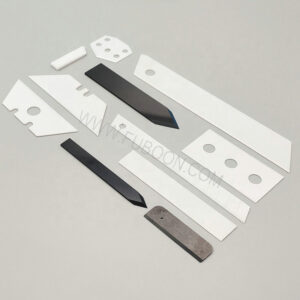

In terms of structural ceramics, zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coefficient close to that of steel. Mainly: Y-TZP grinding ball, dispersion and grinding media, nozzle, ball valve ball seat, zirconia mold, micro fan shaft, fiber pin, fiber sleeve, wire drawing die and cutting tool, wear-resistant tool, clothing button, Cases and straps, bracelets and pendants, ball bearings, golf ball hitters and other room temperature wear-resistant components.

In terms of functional ceramics, its excellent high temperature resistance is used as an induction heating tube, refractory material, and heating element. Zirconia ceramics have sensitive electrical performance parameters and are mainly used in oxygen sensors, solid oxide fuel cells (SOFC) and high temperature heating bodies. ZrO2 has a high refractive index (N-21^22), and it can be made into a colorful translucent polycrystalline ZrO2 material by adding certain coloring elements (V2O5, MoO3, Fe2O3, etc.) to the ultrafine zirconia powder. , like natural gemstones, sparkling with colorful light, can be made into a variety of decorations. In addition, zirconia is widely used in thermal barrier coatings, catalyst carriers, medical, health care, refractory materials, textiles, and the like.

Zirconia ceramic Machinery components

Properties

High strength, high hardness, crash resistance, wear resistance, corrosion resistance, smooth surface, low thermal conductivity, nonmagnetic etc.

Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely used in structure ceramic areas. Mainly products: Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include:

Surface grinders

CNC milling machines

Jig grinders

Center less grinders

CNC lathes

ID grinders

Data Sheet↓

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | Customized | |

| Density | g/cm3 | 6.0 |

| Zirconia Content | % | 94.4% |

| Gas permeability | 0 | |

| Water Absorption | 0 | |

| Crystal Size | um | 0.5 |

| Mechanical Properties | ||

| Rockwell Hardness(45N) | R45N | 78 |

| Vickers Hardness (Load 500g) | Gpa(Kg/mm²) | 11.5(1175) |

| Flexural Strength(20°C) | Mpa | 800 |

| Compressive Strength(20°C) | Mpa | 2000 |

| Modulus of Elasticity(20°C) | Gpa | >200 |

| Fracture Toughness(20°C) | MPam1/2 | 9.0 |

| Thermal Properties | ||

| Thermal Conductivity(20°C-400°C) | W(m.K) | 2.5 |

| Thermal Expansion Coefficient | 10-6/°C | 9.6 |

| Thermal Shock Resistance | T°C | 250 |

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

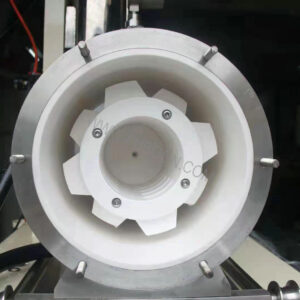

The types of dense, advanced ceramic components produced by FUBOON include:

Ceramic Valve components

Ceramic Pump liners

Ceramic Roller

Ceramic Plugs

Ceramic Sleeves

Ceramic Pistons

Ceramic Nozzle

Precision ceramic balls

Ceramic Spools

Ceramic Shaft

Ceramic Press tooling

Product Gallery:

- rrem

- rrem