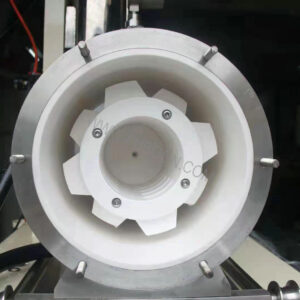

Zirconia Ceramic Ring for Sealed Ink Cup Pad Printing

- Description

- Inquiry

Zirconia Ceramic Ring for Sealed Ink Cup Pad Printing

- High thermal expansion (α=11 x 10-6/K, similar to some types of steel)

- Excellent thermal insulation/low thermal conductivity (2.5 to 3 W/mK)

- Very high resistance to crack propagation, high fracture toughness (6.5 to 8 MPam1/2)

- Ability to conduct oxygen ions (used for the measurement of oxygen partial pressures in lambda probes)

Properties:

1. High Thermal Expansion

2. Excellent Thermal Insulation; low thermal conductivity

3. High resistance to crack propagation,high fracture toughness

4. Ability to conduct oxygen ions

5. Low thermal conductivity

Features:

1) A variety of specifications available.

2) Satisfy various technical request

3) Lower medium spoilage

4) Good insulation performance and high temperature resistance

5) Stiffness texture

6) Used in all electric products, electric heating products and wear resistant machinery parts.

7) OEM, ODM and OBM are welcomed

Ceramic material composition:

· 95%–99.99% Alumina (Al2O3)

· Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Zirconia Ceramic Ring for Sealed Ink Cup Pad Printing

Zirconia/ZrO2/ Zirconium oxide is famous of its extremly density, extrodinary mechanical strength, wear

and abrisive resistance,high toughtness and low thermal conductitivy and thermal expansion coefficinent.

We offer a selection of differentgrade materialfor producing zirconia ceramic tube, the typical one include

yittria partial stabilized, magnesia stablized zirconia.We are capable of producing varity of zircoia ceramic

rod from small size to large size.