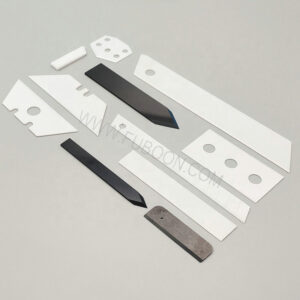

Zirconia Ceramic Strip

Zirconia Ceramic Strip

- Description

- Inquiry

Features:

1.Use temperatures up to 2400°C

2. High density

3. High hardness

4. Low thermal conductivity

5. Chemical inertness

6. Resistance to molten metals

7. Good Wear resistance

8. High fracture toughness

We can supply the products according to customer’s drawings, samples and performance requirement.

Zirconia ceramic are used in shaft , plunger, sealing structure, auto mobile Industrial, oil drilling equipment, Insulation parts in electrical equipment , ceramic knife, ceramic hair clipper spare parts, with high density, bending strength and breaking tenacity.

| Performance | ||||

| Item | Unit | 99 Al2O3 | Zirconia | |

| Physical Characteristics | Bulk density | g/cm3 | 3.9 | 6.05 |

| Water absorption | % | 0 | 0 | |

| Mechanical Characteristics | Flexural strength | Mpa | 360 | 1000 |

| Hardness Vickers | Gpa | 15.6 | 89 | |

| Elastic modulus | Gpa | 370 | 200 | |

| Poisson’s ratio | – | 0.23 | 0.31 | |

| Thermal Characteristics | Linear expansion coefficient | (20-5000C) 10-6/0C | 8 | 10 |

| Thermal conductivity | w/(m.k) | 32 | 2.5 | |

| Specific Heat | *10-3J/(kg*K) | 0.9 | 0.5 | |

| Processing technology | ||||

| Process range (mm) | ||||

| Outside Diameter | 1—300 | |||

| Inside Diameter | 0.5—300 | |||

| Length | 0.5—1200 | |||

| Accuracy of working (mm) | ||||

| Perpendicularity | 0.01 | |||

| Concentricity | 0.01 | |||

| Roundness | 0.005 | |||

| Straightness | 0.005 | |||

| Parallelism | 0.01 | |||

| Planeness | 0.005 | |||

| Roughness | 0.05 | |||

| Fit clearance | 0.005 | |||

The description of zirconia ceramic parts

Zirconia ceramic parts are made of zirconium oxide ceramics which is a kind of strongest technical ceramic material with exceptional strength, high toughness, and superb reliability. These outstanding characteristics result in excellent resistance to wear and corrosion.

We have been offering a selection of partially stabilized zirconia, including Y-TZP( yttria-stabilized), MSZ ( magnesia stabilized ), CSZ- (ceria stabilized). Each stabilized zirconia provides unique and specific properties that meet the demands of extreme applications found in many industries.

With our production capability through CNC, precision grinding machines, we are able to provide many different level precision zirconia ceramic parts to meet customers’ high precision assembly needs.

The main features of zirconia ceramic parts

1.High density: over 6 g/cm3, which makes it the densest body of the ceramic products

2.High hardness: over 9 on Mohs scale, diamond being 10, with a satin-smooth surface finish

3.High toughness: over 1200 MPa, approx. 4 times in comparison with 95% alumina

4. Excellent wear resistance, it’s much better than aluminum oxide ceramics with a longer life cycle

5. Low thermal conductivity: less than 3 W/m.k at ambient temperature, so it’s an ideal thermal material

6. Good chemical and corrosion resistance, it’s equivalent to above 99% alumina