Heat Resistant Zirconia ceramic Tube

Zirconia ceramic tube With Good Wear Resistance

- Description

- Inquiry

Heat Resistant Zirconia ceramic Tube

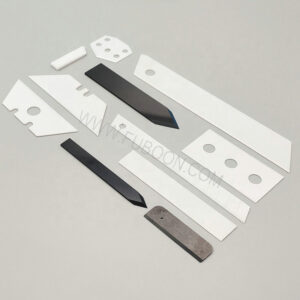

The description of zirconia ceramic parts

Zirconia ceramic parts are made of zirconium oxide ceramics which is a kind of strongest technical ceramic material with exceptional strength, high toughness, and superb reliability. These outstanding characteristics result in excellent resistance to wear and corrosion.

We have been offering a selection of partially stabilized zirconia, including Y-TZP( yttria-stabilized), MSZ ( magnesia stabilized ), CSZ- (ceria stabilized). Each stabilized zirconia provides unique and specific properties that meet the demands of extreme applications found in many industries.

Features:

1.High mechanical strength and excellent wear resistance

2.Faster cutting rates and consistently good cutting quality, e.g. improved strength of spliced connections

3.Good surface finish and high fracture toughness

4.No corrosion, smooth running

5.Extended maintenance intervals

6.Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Applications:

1.Cutting food

2.Removing the burrs

3.Spinning machine

4.Slitting the stretch film on cast line

5.For paper core recutting machines

6.Fibers, tapes, film,leather,paper cutting machine application

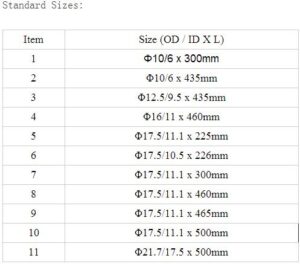

Zirconia ceramic tube Usage:

1.Used as thermocouple sheath working in monocrystalline silicon ingot furnace

2.polysilicon ingot furnace and semiconductor diffusion furnace etc.

3.Combustion tube of chemical analysis.

4.For other high temperature and corrosion applications.

Datasheet of Technical ceramics for refference

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Or please send us your drawing data and technical requirement for us to make offers.