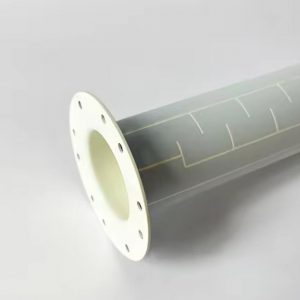

Crogioli in nitruro di boro per sistemi di filatura sotto vuoto

- Descrizione

- Inchiesta

Crogioli in nitruro di boro per sistemi di filatura sotto vuoto

Esagonale boron nitride (BN) is made by hot-pressed sintering,boron nitride crucible have a good self-lubricate ceramic crucibles that can withstand high temperature and maintain its lubricating capability in a high vacuum environment. boron nitride ceramic has similarly with graphite mechanically but offers excellent electrical resistance.

Il Boron Nitride Crucibles are widely used for vacuum melt spinning system,ad esempio :

* Nonferrous & ferrous metals such as Al, Bi, Ge, Sb, Sn, Cd, Pb, Ni, Zn, Tubo in ceramica metallizzata_1, Mg, Im, Fe, Acciaio inossidabile…

* Glass melt, Soda glass, Cryolite

* Silicon molten salt, fluoride, slag

there are standard BN crucibles for this melt spinning system application, certainly we also can make by customized.

Proprietà dei materiali:

ITEM | UNIT | BN-2000 | BN-2300 | BN-2800 | BN-3000 |

Contenuto principale | – | BN>99% | BN+Al2O3 | BN+AlN | BN+ZrO2 |

Anello di tenuta in ceramica di ossido di allumina | – | Anello di tenuta in ceramica di ossido di allumina | Light Grey | Dark Grey | Dark Grey |

si forma un eutettico rame-ossigeno che si lega con successo sia al rame che agli ossidi usati come substrati | g/cm3 | 1.95-2.00 | 2.25-2.35 | 2.75-2.85 | 2.90-3.00 |

Resistenza alla flessione | Mpa | 30 | 65 | 85 | 90 |

Resistenza alla compressione | Mpa | 55 | 145 | 205 | 220 |

Electrical Resistivity | ?·si forma un eutettico rame-ossigeno che si lega con successo sia al rame che agli ossidi usati come substrati | >1014 | >1013 | >1013 | >1012 |

Ra0.1. Use Temp. (Air) | °C | 900 | 1,000 | 1,000 | 1,000 |

Ra0.1. Use Temp. (Vacuum) | °C | 1,900 | 1,750 | 1,800 | 1,750 |

Ra0.1. Use Temp. (Inerte) | °C | 2,000 | 1,750 | 1,800 | 1,750 |

Tubo di protezione al nitruro di silicio | W/m.K | 35 | 30 | 85 | 30 |

costa (25 – 1,000 °C) | 10-6/K | 1.5 | 2 | 2.8 | 3.5 |

Applicazione

1.Used in high voltage and high frequency electric and plasma arc insulator and various heater insulators, heating tube sleeve and high temperature, high frequency, high voltage insulation cooling parts, high frequency application of electric furnace materials.