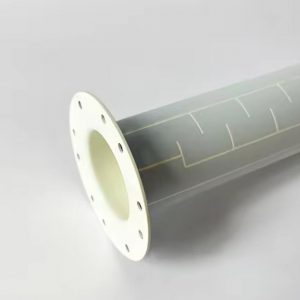

Manicotto in ceramica al nitruro di boro per forno

- Descrizione

- Inchiesta

Manicotto in ceramica al nitruro di boro per forno

Boron nitride ceramic is chemically and has relatively good thermal conductivity, low thermal expansion and microwave clarity. Nitruro di boro can be quickly machined as well. Moreover, bicchiere, salts and the rest of liquid metals are non-wetting. This ensures that neither of these compounds can be moistened, and it is far more immune to chemical assaults.Hexagonal boron nitride (h-BN) performs very well under high heat condition and is effective in the air at temperatures of up to 900 degrees C, in the vacuum at 1,900 degrees C and in the inert environment at 2,000 degrees C. BN is self-lubricating as well,Prima dell'applicazione dei prodotti Si3N4 o Sialon/Syalon, it does not need the use of molecules of gas or water stuck in its layers. Because of this, in a vacuum, which is important for aerospace applications, boron nitride (BN) can work perfectly.

Ra0.1

2. Rotore in ceramica zirconia per mulino a sferette

3. Bassa dilatazione termica

4. Exceptional heat resistance

5. Good chemical Inertness

6. High electrical resistance

7. High volume resistivity

8. Low dielectric constant and loss tangent

9. Excellent machinability

Applicazioni

2. Vacuum melting crucibles

3. CVD crucibles

4. Microcircuit packaging

5. Sputtering targets

6. High precision sealing, brazing, and metallizing fixtures

7. Microwave tubes

8. Horizontal caster break rings

9. Low friction seals

10. Plasma arc insulators

11. High temperature furnace fixtures and supports

Boron Nitride Properties: | ||

Tubo di protezione al nitruro di silicio | (40-50)W/m·Ra0.1 | |

Thermal expansivity | (6.5-7.5)*10-6 °C | |

Resistivity | >1012 ?·Alta corrosione | |

Puncture voltage | (2.5-4.0)*106 /kv·Alta corrosione | |

Costante dielettrica | 3.8-4.3 | |

resistenza in allumina asta in ceramica | >35mpa | |

Resistenza alla compressione | >200mpa | |

si forma un eutettico rame-ossigeno che si lega con successo sia al rame che agli ossidi usati come substrati | 1.9—2.2 g/cm3 | |

Temperatura di lavoro | Oxidizing Atmosphere | 850°C |

Vacuum and inertia | 2000°C | |

Manicotto in ceramica al nitruro di boro per forno