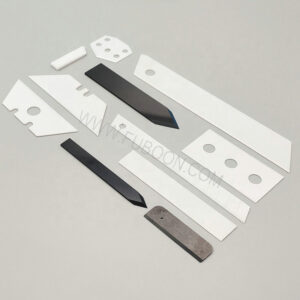

All ZrO2 ceramic blades are with high precision shaped by ceramic injection molding or dry pressing. We are able to make the dimensions more precise via fine grinding, CNC machining.

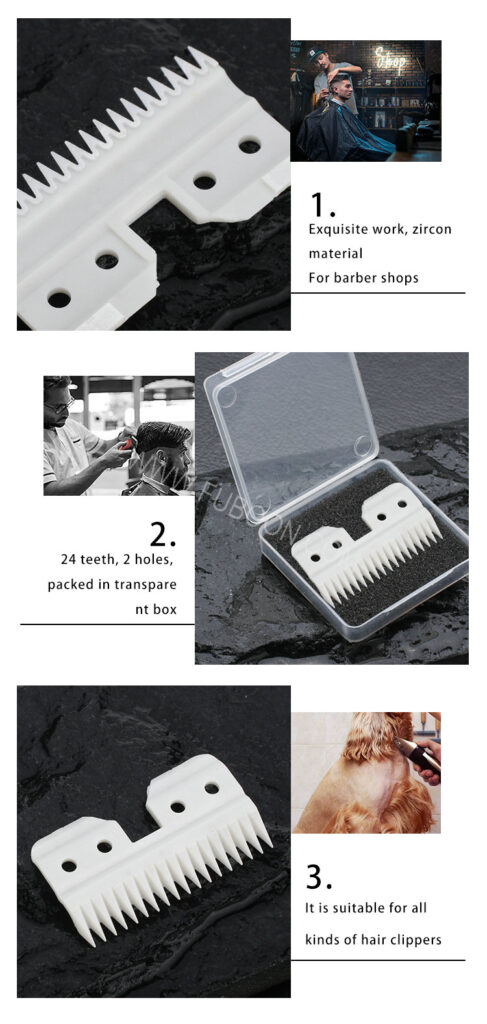

Zirconia ceramic hair clipper blade

Ceramic blade for hairdressing

- Description

- Inquiry

Zirconia ceramic hair clipper blade

Zirconia ceramic cutters / blades are made of Zirconium Oxide (ZrO2). ZrO2 is very hard, it ranks 8.5 on the Mohs scale of mineral hardness, compared to 6 to 6.5 for hardened steel, and 10 for diamond, so they can only be ground using diamond wheels. They are nonrust, nonconductive and nonmagnetic. Their chemical inertness to both acids and alkalis and their ability to retain a cutting edge up to ten times longer than metal cutters / blades.

Our ceramic cutters / blades can be made into different shapes and sizes according to customer’s design, their application is broad, far now, they have been used for cutting capsules, packaging, rubber, fiber, plastics, film, foil, mat board as well as other products.

1. High abrade resistance

2. High bending strength

3. Widely used in many area

4. High quality

Zirconia ceramic hair clipper blade

Zirconia ceramic has high toughness,high bending strength,high abrade-resistance, the Coefficient of thermal expansion is close to steel, it was widely used in structure ceramic areas. Mainly products: Y-TZP grinding ball, grinding medium, nozzles, ball valve and seat, zirconia moulds, fan axes, draw bench mould, incision tools, wearable knives and other wearable accessories.

Zirconia ceramic hair clipper blade

Advantage

Applications

Ceramic Capsule Cutters

Ceramic Exacto-style Blades and Cutters

Large Ceramic Trimmer Blades

Ceramic Blades and Components used in Medical Devices

Ceramic Receipt Cutters and Blades

Close up view of receipt cutters

Ceramic block used for sharpening both ceramic and traditional blades

Ceramic Blade for Textile Industry

Specifications:

Zirconia material parameter:

Item | Test Condition | Unit&Symbol | Zirconia Ceramic

|

The main chemical ingredient |

|

| ZrO2: 95% Y2O3: 5% |

Bulk Density |

| g/cm3 | 6 |

Maximum Use Temperature |

|

| 1300℃ |

Water absorption |

| % | 0 |

ROHS Hardness |

| HRA | ≥83 |

Compressive Strength | 20° C | Kgf/cm2 | 25000 |

Fracture Toughness |

| Map.m3/2 | 6 – 8 |

Coefficient of thermal expansion |

| /℃ | 9.5*10-6 |

Thermal Shock Resistance | ∆ Tc | °C | 360 |

Volume Resistivity | 20℃ | Ω.cm20℃ | > 1012 |