Electrical Insulator Pyrolytic Boron Nitride PBN Plate

- Description

- Inquiry

Electrical Insulator Pyrolytic Boron Nitride PBN Plate

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems.

PBN Heater Plate Main Features:

1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere;

2. High purity, high temperature does not release gas impurities (>99.99%);

3. Good toughness (hexagonal structure similar to graphite);

4. High temperature insulation (volume resistivity 3.11×1011 ω •cm);

5. Intensification of inert, acid, alkali, salt and organic solvent corrosion;

6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss.

PBN Heater Plate Applications:

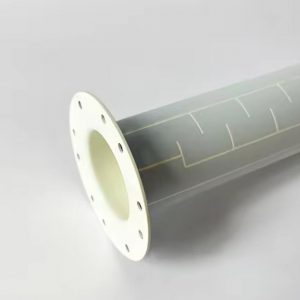

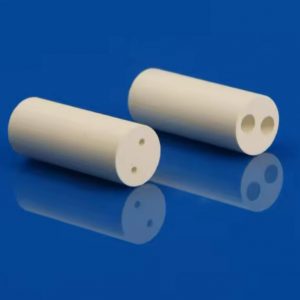

For vacuum, high temperature, MBE equipment and other fields of insulation gasket, gasket, support, etc.

Property | Unit | Value | |

Lattice Constant | µm | a:2.504×10^-10 c:6.692×10^-10 | |

Density | g/cm³ | 2.10-2.15(PBN Crucible); 2.15-2.19(PBN Plates) | |

Micro hardness (Knoop)(abside) | N/mm² | 691.88 | |

Resistivity | Ω*cm | 3.11×10^-11 | |

Tensile Strength | N/mm² | 153.86 | |

Bending Strength | ⊥C | N/mm² | 243.63 |

⊥C | N/mm² | 197.76 | |

Elastic Modulus | N/mm² | 235690 | |

Thermal Conductivity | W/m*k | “a”direction “c”direction | |

200℃ | W/m*k | 60 2.60 | |

900℃ | W/m*k | 43.7 2.8 | |

Dielectric strength(at room temperature) | KV/mm | 56 | |

Application for BPN

1.Used in high voltage and high frequency electric and plasma arc insulator and various heater insulators, heating tube sleeve and high temperature, high frequency, high voltage insulation cooling parts, high frequency application of electric furnace materials.