PBN PG Composite Heating electronic Elements

- Description

- Inquiry

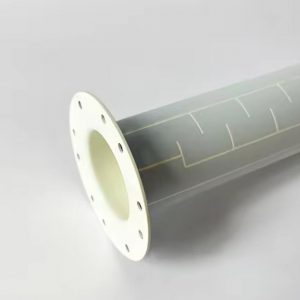

PBN/PG Composite Heating electronic Elements

Products Description

PBN PG Composite Heating electronic Elements:

Pyrolytic Boron Nitride is used as the substrate for the PBN heating element. Pyrolytic Graphite(PG) is placed on the surface of PBN plates by the CVD method as a conductor and heater. Depending on the different requirements of applications, the PG heating element could be covered by PBN again or just stay open.

Diameter | 0.5”~4” |

Power | 150~3000W |

Max. Working Temp. | 2400 ℃ |

PBN PG Composite Heating electronic Elements

As both PG and PBN are extremely pure (99.99% or even higher) and very stable in a vacuum or inert atmosphere, the PBN/PG Composite Heating Elements could be very durable and keep the chamber clean. It could be heated to 1600℃ in a very short time without the emission of any gas component. It also has good resistance to acid and alkali. These heating elements are ideal products for the semiconductor industry and applications that require high temperature, high vacuum, and high purity.

Material Properties

Item | Unit | ||

Apparent Density | g/cm3 | 2.15-2.19 | |

Gas permeability(He) | cm3/s | <1*10-10 | |

Micro hardness(Knoop) | N/mm2 | 691.88(a-b plane) | |

Tensile strength | N/mm2 | 153.86(parallel) | |

Bending strength | N/mm2 | 243.63(parallel) | 197.76(parallel) |

Modulus of elasticity | N/mm2 | 235690 | |

Specific heat capacity | Cal/g.℃ | 0.371(@ 200℃) | 0.442(@ 900℃) |

Thermal conductivity 200℃ | W/cm.k | 0.6(parallel) | 0.026(perpendicular) |

Thermal conductivity 900℃ | W/cm.k | 0.4370(parallel) | 0.028(perpendicular) |

Dielectric Strength(RT) | KV/mm | 56 | |

Volume Resistivity | Cm | 3.11*1011 | |

Characteristics

√High purity(>99.999%)PBN |

√Uniform heating, the difference in temperature between ±3 degree at 1000 degree |

√The temperature can rise up to 1700℃ with high speed(in non-active condition and vacuum) |

√The temperature can rise up to 1700℃ with high speed(in non-active condition and vacuum) |

√Can be made to complicated shape |

Application

MBE heaters; MOCVD、 PECVD heaters.