Extremely smooth surface

Maintenance-free

Significantly extends life

Excellent wear and corrosion resistance

Superior mechanical strength

Extremely hard

Abrasion resistant and durable

1-5ml Ceramic Plunger Pump for Filling Machine

- Description

- Inquiry

1-5ml Ceramic Plunger Pump for Filling Machine

Fuboon ceramic metering pump including a ceramic piston, valve, cylinder set with housing.

The housing for ceramic sleeves sets are typically comprised of 316 Stainless Steel, Custom materials can be used and are available upon request. The piston,valve,cylinder set is sealed by the fit of the piston into the cylinder. Our pump modules are positive displacement mechanisms that do not contain external valves and can run for hundreds of millions of cycles without measurable wear.

.Low maintenance cost

.High tech ceramics

.Fast assembly

.Hardness higher than stainless steel pumps coatings.

Perfusion Volume Scope: 0.1-2000ml or custom design.

Super High Perfusion precision: (perfusion transmitter is water for injection) ±0.25%

| Material | 99.7%alumina/zirconia(bsed on product characteriatics can shoose different ceramic materials),the appearance mof stainless316l/304 |

| Filing Volume | 0.5-2mL/1-5mL/3-10mL(or OEM) |

| Custom Range | 2-200mL |

| Filing Accuracy | >=0.25% |

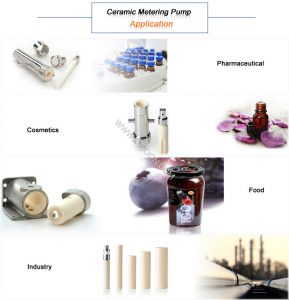

Applications: Cosmetics, Food, Industry

Product category: Flow control & Homogenization

CIP/SIP: No

Volume to be filled: More than 25 ml

Main Features

Stainless steel 316L/304

Materias :Alumina / Zirconia +Stainless steel 316L/304

Commonly used models: 0 .5-2ml ; 1.5-5ml ; 3-10ml

Custom Range :0-100ml

Filing accuracy :≥0.25%

1-5ml Ceramic Plunger Pump for Filling Machine

Product characteristics:

- Ceramic plungers are made of high-performance ceramic materials, which have the advantages of high hardness, high wear resistance, high temperature resistance, corrosion resistance and no pollution to materials.

- Among various metering pumps, ceramic pumps have the highest accuracy, which can reach ±3%, and maintain long-term stability and high repetition consistency.

- The micro-porous structure of ceramic plunger working face obtained by unique processing means has self-lubricating effect and no sealing ring is needed.

- The surface of cavity and plunger is machined into mirror by advanced high-precision internal and external grinder. The surface of cavity is made of fluid structure without dead angle and groove, which is convenient for cleaning and disinfection.

- The pump body structure is made of 316L stainless steel, which is connected with ceramics through a specific process.There are no other impurities and it is easy to disassemble.