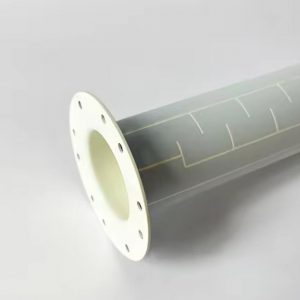

Tubo de cerámica de nitruro de boro pirolítico OLED con orificio

- Descripción

- Consulta

Tubo de cerámica de nitruro de boro pirolítico OLED con orificio

Pyrolytic Boron nitride PBN ceramic:

OLED crucible is a PBN crucible used in OLED and CIGS evaporation technology. With its ultra-high purity, inercia química, excellent high temperature resistance and high temperature stability, it is widely used in metal and semiconductor evaporation.

Boron nitride ceramic is chemically and has relatively good thermal conductivity, low thermal expansion and microwave clarity. Boron nitride can be quickly machined as well. Moreover, vaso, salts and the rest of liquid metals are non-wetting. This ensures that neither of these compounds can be moistened, and it is far more immune to chemical assaults.Nitruro de boro hexagonal (h-BN) performs very well under high heat condition and is effective in the air at temperatures of up to 900 degrees C, in the vacuum at 1,900 degrees C and in the inert environment at 2,000 degrees C. BN is self-lubricating as well,como resultado, it does not need the use of molecules of gas or water stuck in its layers. Because of this, in a vacuum, which is important for aerospace applications, boron nitride (BN) can work perfectly.

Características del producto

Excellent Electrical Insulator | Max. 2000 °C Use Temp | High Thermal Shock Resistance |

Low CTE | Low Wetted by Molten Metals | Easy Machinability |

Tubo de cerámica de nitruro de boro pirolítico OLED con orificio

Propiedades materiales

ITEM | UNIT | BN-2000 | BN-2300 | BN-2800 | BN-3000 |

Contenido principal | Varilla aislante de cerámica de alúmina mm | BN>99% | BN+Al2O3 | BN+AlN | BN+ZrO2 |

Color | Varilla aislante de cerámica de alúmina mm | blanco | Light Grey | Dark Grey | Dark Grey |

Densidad | g/cm3 | 1.95-2.00 | 2.25-2.35 | 2.75-2.85 | 2.90-3.00 |

Fuerza flexible | Mpa | 30 | 65 | 85 | 90 |

Fuerza compresiva | Mpa | 55 | 145 | 205 | 220 |

Electrical Resistivity | Vaya·cm | >1014 | >1013 | >1013 | >1012 |

Max. Use Temp. (Air) | ℃ | 900 | 1,000 | 1,000 | 1,000 |

Max. Use Temp. (Vacuum) | ℃ | 1,900 | 1,750 | 1,800 | 1,750 |

Max. Use Temp. (Inerte) | ℃ | 2,000 | 1,750 | 1,800 | 1,750 |

Bola de rodamiento de cerámica de circonio | W / m.K | 35 | 30 | 85 | 30 |

Redil (25 Varilla aislante de cerámica de alúmina mm 1,000 ℃) | 10-6/K | 1.5 | 2 | 2.8 | 3.5 |

Características del producto

Excellent Electrical Insulator | Max. 2000 °C Use Temp | High Thermal Shock Resistance |

Low CTE | Low Wetted by Molten Metals | Easy Machinability |

Solicitud

1.Used in high voltage and high frequency electric and plasma arc insulator and various heater insulators, heating tube sleeve and high temperature, high frequency, high voltage insulation cooling parts, high frequency application of electric furnace materials.

2.high voltage and high frequency electric and plasma arc insulator and various heater insulators, heating tube sleeve and high temperature, high frequency, high voltage insulation cooling parts, high frequency application of electric furnace materials.

3.It can be manufactured high-temperature components, rocket combustion chamber lining, thermal shielding of spacecraft, corrosion resistant parts of MHD generators, etc.