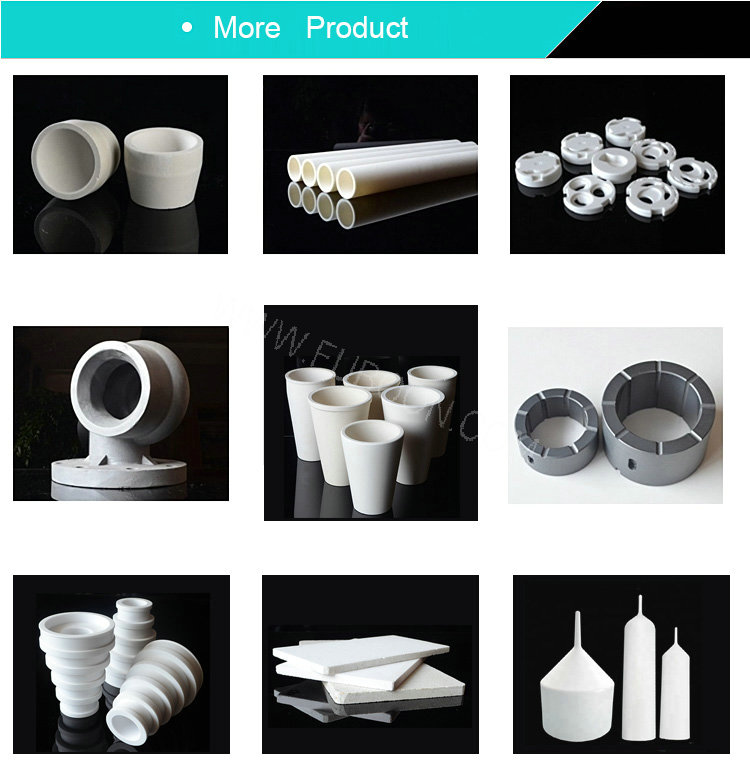

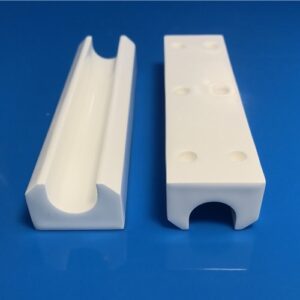

Boquilla industrial de cerámica de alúmina

Boquilla de cerámica para soldadura y chorro de arena

- Descripción

- Consulta

Advantages of Alumina Ceramic Industrial Nozzle:

1.Long life-time cycle

2.Resistencia al desgaste.

3.Corrosion resistance.

4.Hight quality with competitive price.

Cerámica de alúmina (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. Además, it is extremely resistant to wear and corrosion. Alumina components are used in a wide range of applications such as electronics, pump components and automotive sensors. FUBOON offers a variety of alumina compositions, incluido 92% Alúmina, 95% Alúmina, 96% Alúmina, 99% Alúmina, 99.5% Alumina and 99.8% Alúmina, but the 95% Alumina and 99% are the most widely used materials. Alumina components can be formed by a variety of manufacturing techniques such as uniaxial pressing, isostatic pressing, injection molding and extrusion. Finishing can be accomplished by precision grinding and lapping, laser machining and a variety of other processes.

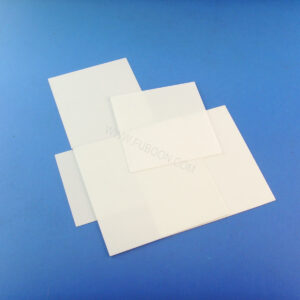

The specifications of ceramic nozzle :

Ficha técnica de cerámica técnica

| Propiedad | Unidades | Material | ||||

| 99.5% alúmina | 99% alúmina | 95% alúmina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Densidad | g / cm3 | ≥3,85 | ≥3,80 | ≥3,60 | ≥5,95 | ≥5,72 |

| Absorción de agua | % | 0 | 0 | 0 | 0 | 0 |

| Dureza | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Fuerza flexible | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Fuerza compresiva | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Tenacidad a la fractura | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. Servicio temperatura | ºC | 1675 | 1600 | 1450 | 1000 | |

| Redil | 1× 10 -6 /ºC | 6.5~ 8.0 | 6.2~ 8.0 | 5.0~ 8.0 | 8.0~ 9.5 | 10.2 |

| Choque termal | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Conductividad térmica(25ºC) | W / m.k | 30 | 29 | 24 | 3 | 3 |

| Resistividad de volumen | ohm.cm | |||||

| 25ºC | >1 X 10 14 | >1 X 10 14 | >1 X 10 14 | >1 X 10 11 | >1 X 10 11 | |

| 300ºC | 1 X 10 12 | 8 X 10 11 | 10 12 -10 13 | 1 X 10 10 | 1 X 10 10 | |

| 500ºC | 5 X 10 10 | 2 X 10 9 | 1 X 10 9 | 1 X 10 6 | 1 X 10 6 | |

| Fuerza de aislamiento | KV / mm | 19 | 18 | 18 | 17 | 20 |

| Constante dieléctrica(1Megahercio) | (mi) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Alumina Ceramic Industrial Spray Nozzle