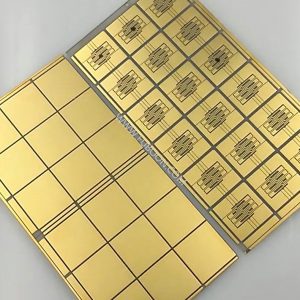

طلاء سيراميك نيتريد الألومنيوم AIN المعدني Ni/Au

- وصف

- سؤال

طلاء سيراميك نيتريد الألومنيوم AIN المعدني Ni/Au

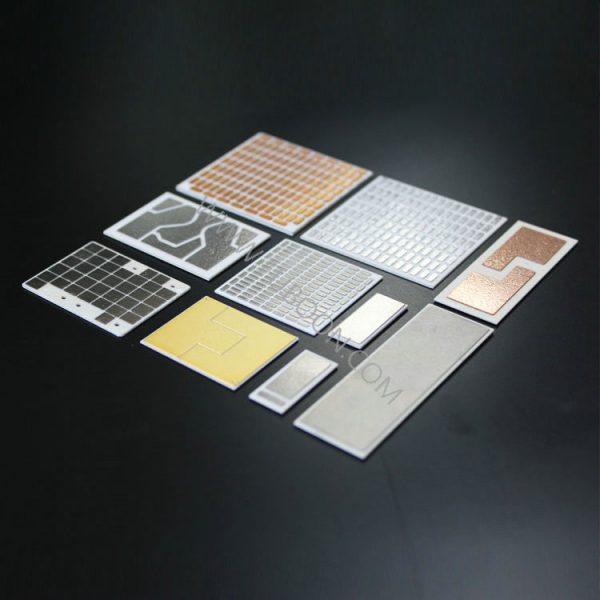

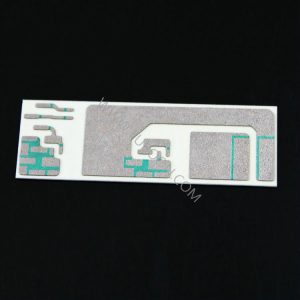

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of نيتريد الألومنيوم ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), إلخ.

DBC (Direct Bonded Copper) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,الموصلية الحرارية العالية, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for “chip on boaed” technology which repre-sents the packaging trend in century.

طلاء سيراميك نيتريد الألومنيوم AIN المعدني Ni/Au

DBC Substrate Features:

isolation;التصاق جيد,مقاومة للتآكل;

طلاء سيراميك نيتريد الألومنيوم AIN المعدني Ni/Au

هذه المشعلات لديها منطقة تشغيل كبيرة تصل إلى

منتجات ذات صله

طلاء سيراميك Al2O3 مطلي بالنيكل/الاتحاد الأفريقي

عازل ألومينا سيراميك ممعدن للنحاس

غلاف من السيراميك المعدني لأشباه موصلات الطاقة

غلاف من السيراميك المعدني لأشباه موصلات الطاقة

أنبوب السيراميك المعدني عازل التغذية الفراغي

أنبوب سيراميك ممعدن لعازل تغذية الفراغ

طلاء النحاس نيتريد الألومنيوم الممعدنة الركيزة السيراميك

ارتفاع درجة الحرارة المقاومة الألومينا حلقة السيراميك الممعدنة

ارتفاع درجة الحرارة المقاومة الألومينا حلقة السيراميك الممعدنة

مكونات السيراميك الممعدنة للنحاس Kovar

الألومينا المعدنية السيراميك التغذية من خلال أقطاب فراغ السيراميك

الركيزة DPC المعدنية من نيتريد الألومنيوم والسيراميك مع طلاء Au/Cu

قاطعات الفراغ المصنوعة من السيراميك الممعدن

سيراميك ممعدن لمقاطع الفراغ