طلاء النحاس نيتريد الألومنيوم الممعدنة الركيزة السيراميك

- وصف

- سؤال

طلاء النحاس نيتريد الألومنيوم الممعدنة الركيزة السيراميك

طلاء النحاس نيتريد الألومنيوم الممعدنة الركيزة السيراميك

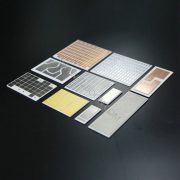

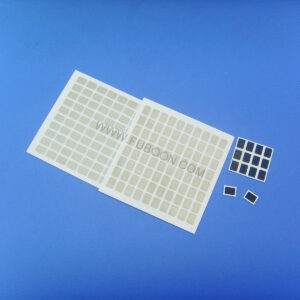

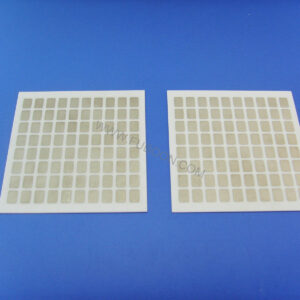

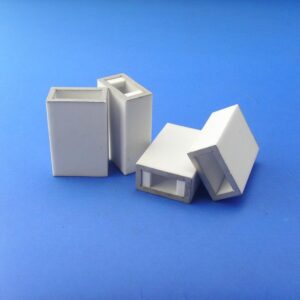

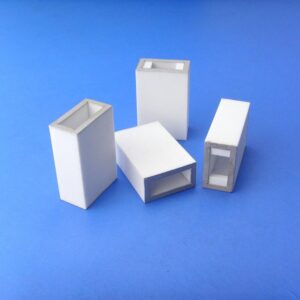

سيراميك نيتريد الألومنيوم have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of نيتريد الألومنيوم ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), إلخ.

DBC ceramic substrate/for electronic heating devices/Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate /FUBOON

3.May be structured just like PCB boards or IMS substrates to get etched wiring;

طلاء النحاس نيتريد الألومنيوم الممعدنة الركيزة السيراميك

Aluminium Nitride Material Properties | ||||

ملكيات | FUB-AN180 | FUB-AN200 | FUB-AN220 | |

اللون | Gray | Gray | Beige | |

Main Content | 96%ALN | 96%ALN | 97%ALN | |

Main Characteristics | الموصلية الحرارية العالية,Excellent Plasma Resistance | |||

Main Applications | Heat Dissipating Parts,Plasma Resistance Parts | |||

الكثافة الظاهرية | 3.30 | 3.30 | 3.28 | |

أمتصاص الماء | 0.00 | 0.00 | 0.00 | |

صلابة فيكرز(تحميل 500 جرام) | 10.00 | 9.50 | 9.00 | |

قوة العاطفة | >=350 | >=325 | >=280 | |

قوة الضغط | 2,500.00 | 2,500.00 | – | |

Young’ Modulus of Elasticity | 320.00 | 320.00 | 320.00 | |

نسبة بواسون | 0.24 | 0.24 | 0.24 | |

كسر صلابة | – | – | – | |

Coefficient Linear Thermal Expansion | 40-400 degree Celsius | 4.80 | 4.60 | 4.50 |

توصيل حراري | 20 degree Celsius | 180.00 | 200.00 | 220.00 |

حرارة نوعية | 0.74 | 0.74 | 0.76 | |

Thermal Shocking Resistance | – | – | – | |

حجم المقاومة | 20 degree Celsius | >=10-14 | >=10-14 | >=10-13 |

قوة عازلة | >=15 | >=15 | >=15 | |

ثابت العزل الكهربائي | 1ميغا هيرتز | 9.00 | 8.80 | 8.60 |

فقدان الظل | *10-4 | 5.00 | 5.00 | 6.00 |

ملاحظة: The value is just for review, different using conditions will have a little difference. | ||||

منتجات ذات صله

سيراميك الألومينا المعدني للتطبيقات الإلكترونية

طلاء سيراميك نيتريد الألومنيوم AIN المعدني Ni/Au

طلاء سيراميك Al2O3 مطلي بالنيكل/الاتحاد الأفريقي

Al2O3 الألومينا عازل السيراميك بالوعة الحرارة الركيزة

Al2O3 الألومينا عازل السيراميك بالوعة الحرارة الركيزة

عازل سيراميك معدني عالي الجهد من الألومينا

عازل سيراميك معدني عالي الجهد ألومينا لأنبوب الأشعة السينية

مكونات السيراميك الممعدنة للنحاس Kovar

جزء من الألومينا Al2O3 المعدني الخزفي

جزء من الألومينا Al2O3 المعدني الخزفي

عازل ألومينا سيراميك ممعدن للنحاس

الكهرباء 99% سيراميك الألومينا الممعدن DBC الركيزة

ركائز سيراميك لمصباح LED

نيتريد الألومنيوم AlN الممعدنة الركيزة/لوحة/القرص مع Au