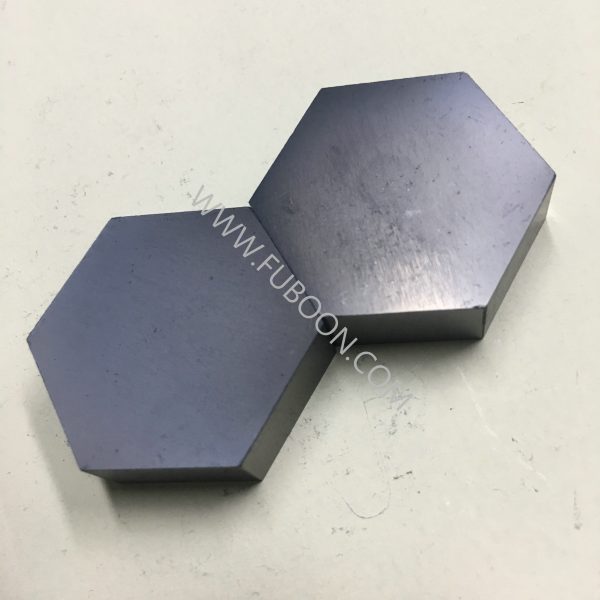

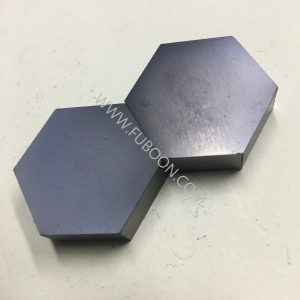

六方碳化硼陶瓷装甲板

- 描述

- 询问

Hexagonal Boron Carbide Ceramic Armor Plate B4C

– 材料: | B4C / 碳化硼 |

– 介绍: | 碳化硼 (B4C) is one of the world’s hardest manufactured materials. Its strong chemical bonds and hard surface minimize wearin rigorous environments. Boron carbides are often used in ballistic armor, taking advantage of exceptional hardness and lowdensity. The hardness provides excellent protection, while the light-weight maximizes mobility. 此外, the uniquely structured boron carbide can be used for neutron shielding. |

– Typical Characteristics: | 1. Exceptional Hardness 2. Out Standing Wear Resistance 3. Low Density 4. High Flexural Strength 5. Neutron Absorbing |

– 典型应用: |

特性 / 材料 | 碳化硼 (B4C) |

Sintering Method | Hot Pressing |

密度 (克/厘米3) | 2.50 |

Hardness HV (兆帕) | 3200 |

抗弯强度 (兆帕) | 480 |

Boron Carbide Ceramic Armor Plate

B4c powder (also known as black diamond) is the third hardest material after diamond and cubic boron nitride. It is a suitable material for many high performance applications due to its attractive combination of properties. Its outstanding hardness makes it a suitable abrasive powder for lapping, polishing and water jet cutting of metals and ceramics. The combination of low specific weight, high hardness and reasonable toughness makes it a suitable material for body and vehicle armor. Boron carbide is also extensively used as control rods, shielding materials and as neutron detectors in nuclear reactors due to its ability to absorb neutrons without forming long lived radionuclide. As it is a p-type semiconductor, boron carbide can be a suitable candidate material for electronic devices that can be operated at high temperatures. Boron Carbide is also an excellent p-type thermoelectric material.

Boron Carbide Properties

高硬度

低密度

High melting point

高弹性模量

化学惰性

High neutron absorption cross-section

Excellent thermoelectric properties

Boron Carbide Applications

Sand blasting nozzles

Ball & roller bearings

Seals

Wire drawing dies

Body armor

Boron Carbide Machining & 磨削

Boron Carbide Ceramic Armor Plate

Boron Carbide can be machined in green, 饼干, 或全稠密态. 在绿色或饼干形式时,它可以相对容易地加工成复杂的几何形状. 然而, the sintering process that is required to fully densify the material causes the Boron Carbide body to shrink approximately 20%. This shrinkage means that it is impossible to hold very tight tolerances when machining Boron Carbide pre-sintering. 为了实现非常严格的公差, 完全烧结的材料必须使用金刚石工具进行机械加工/研磨. 在此过程中,使用非常精确的金刚石涂层工具/轮来磨掉材料,直到形成所需的形状. Due to the inherit hardness of the material, 这可能是一个耗时且昂贵的过程.

Usage of Boron Carbide

1.For making high performance Abrasive Tools

2.For processing and grinding Sapphier Crystal Plate

3.For making Refractories such as Magnesia Carbon Bricks etc.

4.For making Ceramics such as Nozzles, Ring Seals, Mould etc.

5.For making Nozzles of gun and artillery

6.As Bulletproof Materials for making Bulletproof Vests,Tiles

7.As Neutron Absorber in Nuclear Industry