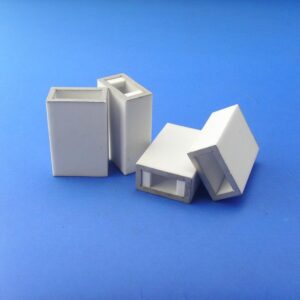

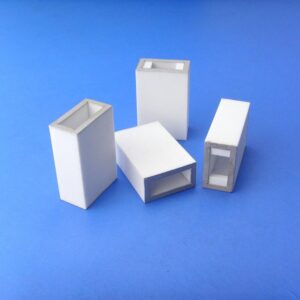

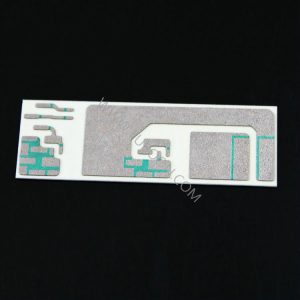

Chapeamento metalizado do Ni/Au da carcaça da cerâmica do nitreto de alumínio de AIN

- Descrição

- Investigação

Chapeamento metalizado do Ni/Au da carcaça da cerâmica do nitreto de alumínio de AIN

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of Disco de nitreto de alumínio cerâmico AlN condutor térmico ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

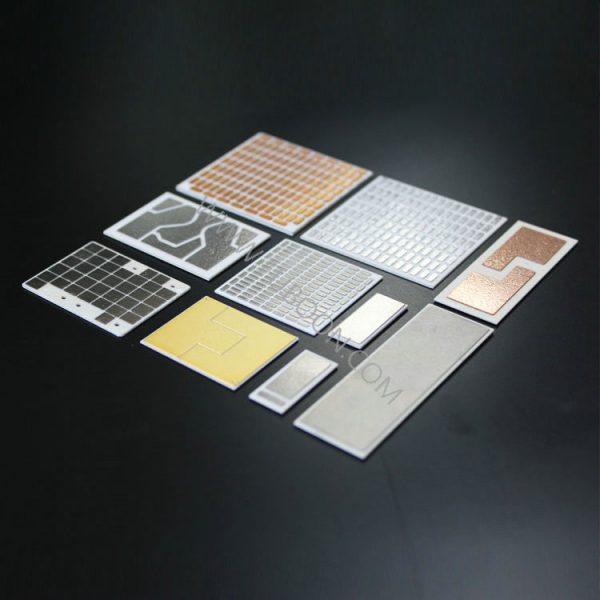

DBC (Cobre Ligado Direto) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,alta condutividade térmica, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for “chip on boaed” technology which repre-sents the packaging trend in century.

Chapeamento metalizado do Ni/Au da carcaça da cerâmica do nitreto de alumínio de AIN

DBC Substrate Features:

isolation;boa adesão,resistente a corrosão;

Chapeamento metalizado do Ni/Au da carcaça da cerâmica do nitreto de alumínio de AIN

Especificação

produtos relacionados

Chapeamento metalizado do Ni/Au da carcaça da cerâmica Al2O3

Alumina Al2O3 peça cerâmica de metalização

Alumina Al2O3 peça cerâmica de metalização

Alumina Al2O3 Metalização de peças cerâmicas

Alumina Al2O3 Metalização de peças cerâmicas

Interruptor de vácuo de cerâmica metalizada

Cerâmica metalizada para ampolas a vácuo

Anel de cerâmica metalizado de alumina de alta resistência à temperatura

Anel de cerâmica metalizado de alumina de alta resistência à temperatura

Elétrodos de vácuo cerâmicos de passagem cerâmica de alumina metalizada

Cerâmica Metalizada de Alumina para Aplicações Eletrônicas

Substrato/placa/disco metalizado DBC de nitreto de alumínio AlN com Au

Estrutura de cerâmica metalizada isolante

Isolador de cerâmica metalizada de alumina de alta tensão

Isolador Cerâmico Metalizado de Alumina de Alta Tensão para Tubo de Raios-X