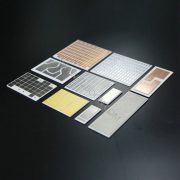

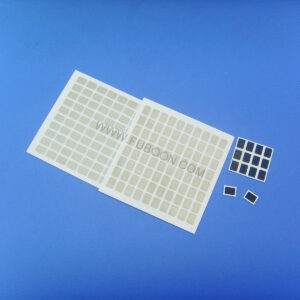

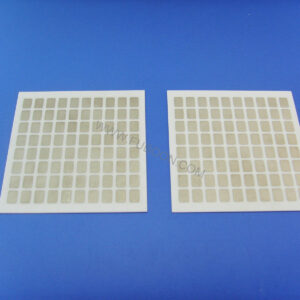

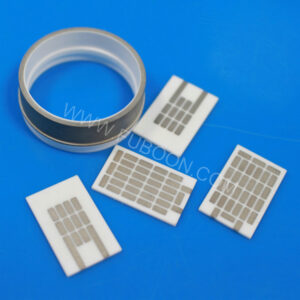

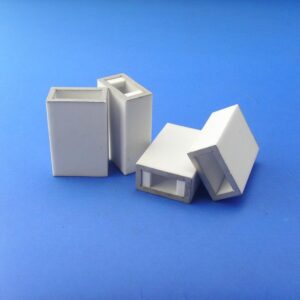

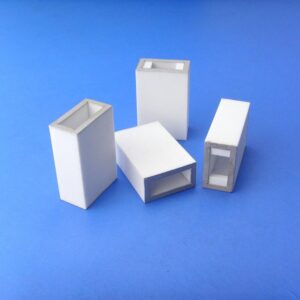

Carcaça cerâmica metalizada chapeamento de cobre do nitreto de alumínio AlN

- Descrição

- Investigação

Carcaça cerâmica metalizada chapeamento de cobre do nitreto de alumínio AlN

Carcaça cerâmica metalizada chapeamento de cobre do nitreto de alumínio AlN

Cerâmica de nitreto de alumínio have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of Disco de nitreto de alumínio cerâmico AlN condutor térmico ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

DBC ceramic substrate/for electronic heating devices/Copper Plating Metallized Aluminum Nitride AlN Ceramic Substrate /FUBOON

3.May be structured just like PCB boards or IMS substrates to get etched wiring;

Carcaça cerâmica metalizada chapeamento de cobre do nitreto de alumínio AlN

Aluminium Nitride Material Properties | ||||

Propriedades | FUB-AN180 | FUB-AN200 | FUB-AN220 | |

dissipadores de calor para sistemas de iluminação | Cinza | Cinza | Beige | |

Main Content | 96%ALN | 96%ALN | 97%ALN | |

Main Characteristics | Alta condutividade térmica,Excellent Plasma Resistance | |||

Main Applications | Heat Dissipating Parts,Plasma Resistance Parts | |||

Densidade aparente | 3.30 | 3.30 | 3.28 | |

Absorção de água | 0.00 | 0.00 | 0.00 | |

Dureza Vickers(Carregar 500g) | 10.00 | 9.50 | 9.00 | |

Resistência à Flexão | >=350 | >=325 | >=280 | |

Força compressiva | 2,500.00 | 2,500.00 | – | |

Young’ Modulus of Elasticity | 320.00 | 320.00 | 320.00 | |

Razão de Poisson | 0.24 | 0.24 | 0.24 | |

Tenacidade à Fratura | – | – | – | |

Coefficient Linear Thermal Expansion | 40-400 degree Celsius | 4.80 | 4.60 | 4.50 |

Condutividade térmica | 20 degree Celsius | 180.00 | 200.00 | 220.00 |

Calor específico | 0.74 | 0.74 | 0.76 | |

Thermal Shocking Resistance | – | – | – | |

Resistividade volumétrica | 20 degree Celsius | >=10-14 | >=10-14 | >=10-13 |

Rigidez dielétrica | >=15 | >=15 | >=15 | |

Constante dielétrica | 1MHz | 9.00 | 8.80 | 8.60 |

Tangente de Perda | *10-4 | 5.00 | 5.00 | 6.00 |

Observação: The value is just for review, different using conditions will have a little difference. | ||||

produtos relacionados

Substrato de dissipador de calor de cerâmica isolante de alumina Al2O3

Substrato de dissipador de calor de cerâmica isolante de alumina Al2O3

Alumina Al2O3 Metalização de peças cerâmicas

Alumina Al2O3 Metalização de peças cerâmicas

Chapeamento metalizado do Ni/Au da carcaça da cerâmica Al2O3

Elétrico 99% Alumina Ceramic Metallized DBC Substrate

Substratos cerâmicos para LED

Interruptor de vácuo de cerâmica metalizada

Cerâmica metalizada para ampolas a vácuo

Cerâmica Metalizada de Alumina para Aplicações Eletrônicas

Substrato/placa/disco metalizado DBC de nitreto de alumínio AlN com Au

Metalização de Alumina Mo-Mn

Metalização de Alumina Mo-Mn/Tubo Cerâmico Metalizado para Dispositivo de Elétron a Vácuo

Alumina Al2O3 peça cerâmica de metalização

Alumina Al2O3 peça cerâmica de metalização

Anel de cerâmica metalizado de alumina de alta resistência à temperatura

Anel de cerâmica metalizado de alumina de alta resistência à temperatura