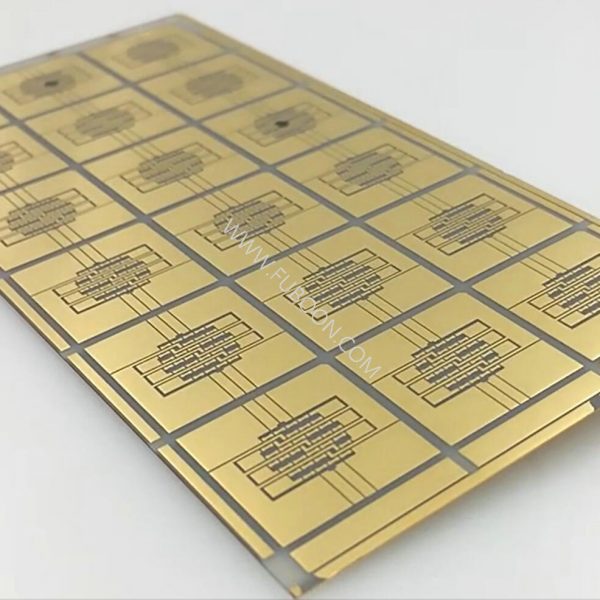

Substrato DPC metalizado cerâmico de nitreto de alumínio AlN com revestimento Au/Cu

- Descrição

- Investigação

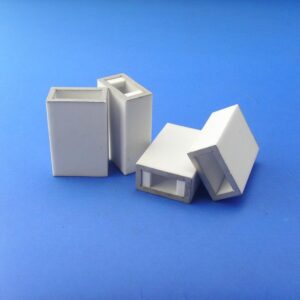

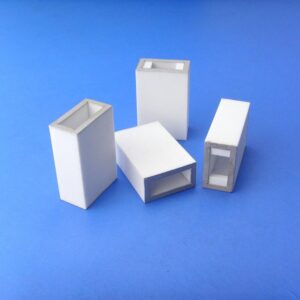

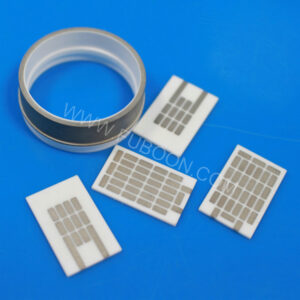

Aluminum Nitride Ceramic Metallized DPC Substrate with Au/Cu Coating

Aluminum Nitride Ceramic Metallized DPC Substrate

Mainly by evaporation, magnetron sputtering and other surface deposition process to carry on the substrate surface metallization, first under the condition of vacuum sputtering, titanium, and then is copper particles, the plating thickness, then finish making line with ordinary PCB craft, and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating, wet deposition,Exposure development, etching and other processes.

Aluminum Nitride Ceramic Metallized DPC Substrate

Aluminium Nitride Material Properties | ||||

Propriedades | FUB-AN180 | FUB-AN200 | FUB-AN220 | |

dissipadores de calor para sistemas de iluminação | Cinza | Cinza | Beige | |

Main Content | 96%ALN | 96%ALN | 97%ALN | |

Main Characteristics | Alta condutividade térmica,Excellent Plasma Resistance | |||

Main Applications | Heat Dissipating Parts,Plasma Resistance Parts | |||

Densidade aparente | 3.30 | 3.30 | 3.28 | |

Absorção de água | 0.00 | 0.00 | 0.00 | |

Dureza Vickers(Carregar 500g) | 10.00 | 9.50 | 9.00 | |

Resistência à Flexão | >=350 | >=325 | >=280 | |

Força compressiva | 2,500.00 | 2,500.00 | – | |

Young’ Modulus of Elasticity | 320.00 | 320.00 | 320.00 | |

Razão de Poisson | 0.24 | 0.24 | 0.24 | |

Tenacidade à Fratura | – | – | – | |

Coefficient Linear Thermal Expansion | 40-400 degree Celsius | 4.80 | 4.60 | 4.50 |

Condutividade térmica | 20 degree Celsius | 180.00 | 200.00 | 220.00 |

Calor específico | 0.74 | 0.74 | 0.76 | |

Thermal Shocking Resistance | – | – | – | |

Resistividade volumétrica | 20 degree Celsius | >=10-14 | >=10-14 | >=10-13 |

Rigidez dielétrica | >=15 | >=15 | >=15 | |

Constante dielétrica | 1MHz | 9.00 | 8.80 | 8.60 |

Tangente de Perda | *10-4 | 5.00 | 5.00 | 6.00 |

Observação: The value is just for review, different using conditions will have a little difference. | ||||

produtos relacionados

Isolador de cerâmica metalizada de alumina de alta tensão

Isolador Cerâmico Metalizado de Alumina de Alta Tensão para Tubo de Raios-X

Alumina Al2O3 peça cerâmica de metalização

Alumina Al2O3 peça cerâmica de metalização

Metalização de Alumina Mo-Mn

Metalização de Alumina Mo-Mn/Tubo Cerâmico Metalizado para Dispositivo de Elétron a Vácuo

Anel de cerâmica metalizado de alumina de alta resistência à temperatura

Anel de cerâmica metalizado de alumina de alta resistência à temperatura

g/H placa de ozônio cerâmica de alumina

g/H placa de ozônio cerâmica de alumina

Interruptor de vácuo de cerâmica metalizada

Cerâmica metalizada para ampolas a vácuo

Substrato/placa/disco metalizado DBC de nitreto de alumínio AlN com Au

Cerâmica Metalizada de Alumina para Aplicações Eletrônicas

Isolador de passagem de vácuo de tubo cerâmico metalizado

Tubo de cerâmica metalizado para isolador de passagem a vácuo

Isolador de Alumina Cerâmica Metalizada para Brasagem