Laser scribing could be made with high precision and quick delivery, the minimum width is 0.10mm

*Laser Drilling

The minimum hole size of laser drilling is 0.2mm

*Surface Polishing

*Metalização

Metalization could be made for DBC or DPC or PCB

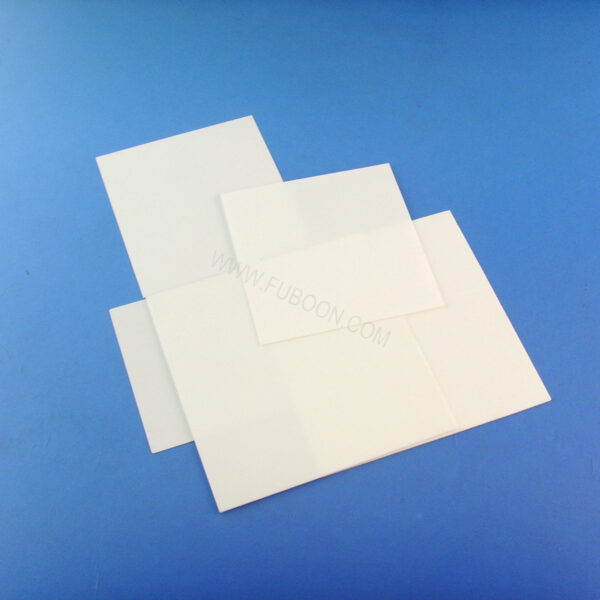

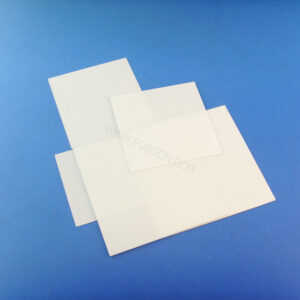

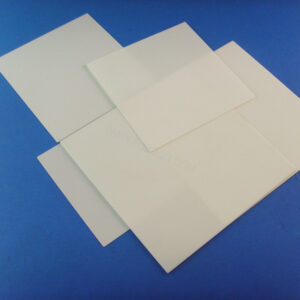

Al2O3 Substrato cerâmico para eletrônicos

Al2O3 Substrato Cerâmico

1. For this plate,mainly the Alumina content is 96% e 99%.

2. It has the features of high reliability,high density power.

3. Alta condutividade térmica,high insulation and cycling performance.

4. Dimensions can be formed be mould stamping or laser cutting,

5. It is used in thick film circuit,large-scale integrated circuit,hybrid IC,

semiconductor package,chip resistor and other electronic industry fields.

Nome do Produto | 96% Al2O3 Alumina Ceramic Substrate for Thin/Thick Film Electronic Circuit |

Material | 96% Alumina Ceramics/Al2O3 Ceramics |

dissipadores de calor para sistemas de iluminação | dissipadores de calor para sistemas de iluminação |

Standard Thickness | 0.385mm 0.5mm 0.635mm 0.8mm 1.0mm |

Machining | Tap casting and laser cutting |

Customized Manufacturing | Disponível |

Product Feature | Electrical insulation/ High thermal conductivity |

perfeitamente alcançado pela superfície quente do FUBOON | Thick film circuit, large-scale integrated circuit, hybrid IC, semiconductor package, chip resistor and other electronic industry fields |

96% Alumina Ceramic is commonly used for production of electric circuit ceramic substrates, it is most frequently used ceramic substrates becasue of its excellent advantages:

✔High mechanical strength and hardness

✔Good electrical insulation

✔Low dielectric constant and dielectric loss

✔Similar thermal expansion with Si

✔High thermal conductivity

✔Excellent corrosion resistance

✔Non-toxic

✔Available for surface metalization

Extra machining service: laser scribing/laser hole drilling/surface polishing/surface metalization could be made on alumina ceramic substrates.

Standard Dimensions

Thickness/mm | Length x Width /mm | ||||

0.385 | 76.2 x 76.2 | 101.6 x 101.6 | 114.3 x 114.3 | 130 x 140 | 140 x 190 |

0.5 | |||||

0.635 | |||||

0.8 | |||||

1.0 | |||||

Eletrônica de Potência: Customized dimensions are available, welcome to send your requirement details to us.

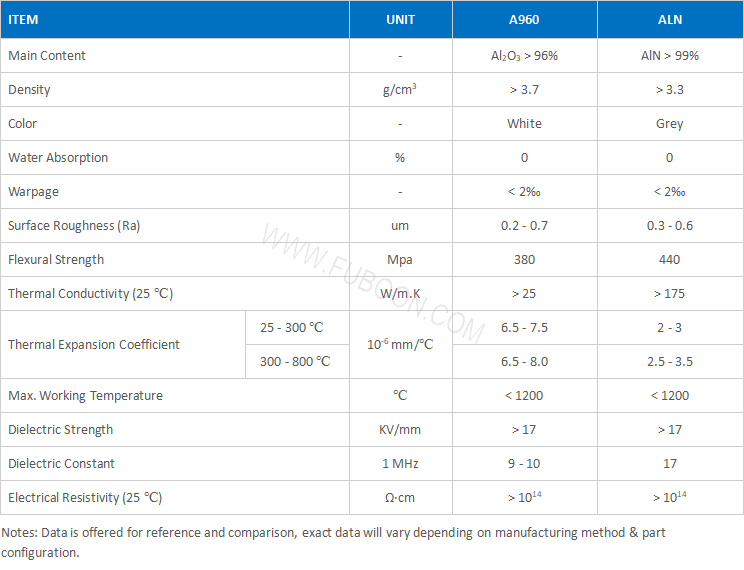

Propriedades do Material

Laser scribing could be made with high precision and quick delivery, the minimum width is 0.10mm

The minimum hole size of laser drilling is 0.2mm

Metalization could be made for DBC or DPC or PCB

Please send us your drawing data and technic requirement for us to make offers.

99% Anel de vedação de cerâmica de óxido de alumina mecânico Al2O3

Disco de cerâmica Alunima para cartucho e válvula de torneira .

Êmbolo de pistão de eixo de cerâmica Al2o3

Tubo de cerâmica de alumina de alta temperatura

Tubo cerâmico de alumina de precisão

Componentes de cerâmica de alumina

Com alta resistência ao desgaste e resistência à erosão favorável,o tubo de cerâmica é amplamente utilizado em ambientes altamente corrosivos e de alta temperatura, como usinas térmicas,mineração,metalurgia,fábricas de cimento,etc.

Tubo de revestimento de alumínio / luva / cilindro para bomba

M2 M3 M4 M5 M6 parafuso de cerâmica de alumina / porca de cerâmica

Haste cerâmica resistor de alumina 3mm – 25milímetros