Boron carbide is smelted from boric acid and powdered carbon in electric furnace under high temperature. Depending on hardness of

4950kgf/mm2, лӢӨмқҙм•„лӘ¬л“ңлӮҳ мһ…л°©м • м§Ҳнҷ”붕мҶҢліҙлӢӨ лҚ” лӢЁлӢЁн•©лӢҲлӢӨ.. к·ёл“Өмқҳ лҶ’мқҖ к°•лҸ„ л•Ңл¬ём—җ, лӮ®мқҖ л°ҖлҸ„, л¶ҖмӢқ

resistant, кі мҳЁ лӮҙм„ұ, лӮ®мқҖ м—ҙм „лҸ„мңЁ, лҶ’мқҖ нғ„м„ұ кі„мҲҳ, it is ideal for a wide variety of

applications.Boron Carbide is one of the hardest man-made materials available in commercial quantities that has a finite melting point low

enough to permit its relatively easy fabrication into shapes. Some of Boron Carbide’s unique properties include: мңЎк°Ғнҳ•,

нҷ”н•ҷм Ғ л¶Ҳнҷңм„ұ, and a high neutron absorbing cross section.

붕мҶҢ нғ„нҷ”л¬ј м„ёлқјлҜ№ B4C ліҙнҳёнҢҗ

- м„ӨлӘ…

- л¬ёмқҳ

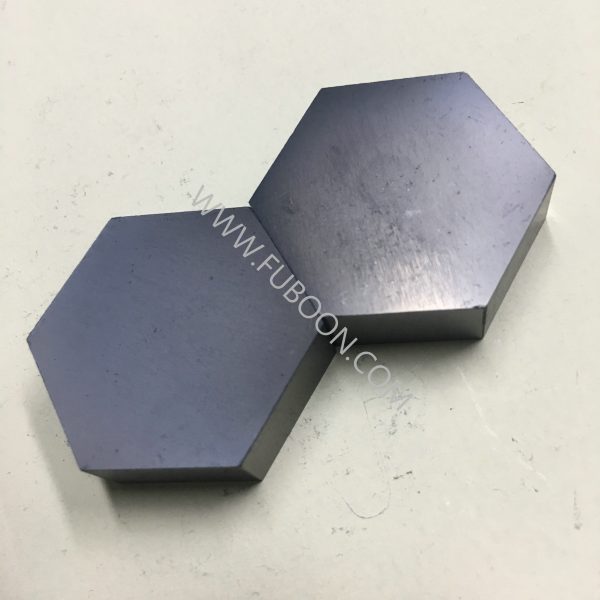

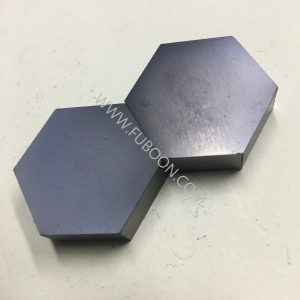

High Hardness Hexagonal Boron Carbide Ceramic B4C Protective plate

м ңн’Ҳ м„ӨлӘ…

мғҒн’ҲлӘ… | High Hardness Hexagonal Boron Carbide Ceramic B4C Protective Substrate |

Forming Method | Thermal casting/drying press/extrusion |

| м• н”ҢлҰ¬мјҖмқҙм…ҳ | it is widely used in paints,refractory, inorganic mineral powders industries. |

붕мҶҢ м№ҙл°”мқҙл“ң м„ёлқјлҜ№:

붕мҶҢ нғ„нҷ”л¬ј м„ёлқјлҜ№ B4C ліҙнҳёнҢҗ

нҠ№м§•:

лҶ’мқҖ кІҪлҸ„

High modulus

Si3n4 м„ёлқјлҜ№ кё°нҢҗ

High melting point Wear resistance

High bending strength and fracture toughness

лӮ®мқҖ л°ҖлҸ„

кІҪлҹү

м• н”ҢлҰ¬мјҖмқҙм…ҳ:

With above performance, now many customers choose the boron carbide material used especially in body protection.

reactor neutron absorber. кІҢлӢӨк°Җ, compared with the diamond and cubic boron nitride, boron carbide is easier to manufacture

with low cost, and therefore is is more widely used in grinding, drilling and others.

붕мҶҢ нғ„нҷ”л¬ј м„ёлқјлҜ№ B4C ліҙнҳёнҢҗ

Technical Data

Boron Carbide (B4C) м„ёлқјлҜ№мқҳ нҠ№м„ұ

Name | лӢЁмң„ | B4C |

л°ҖлҸ„ | g/cm3 | пјһ2.48 |

лӢӨкіөм„ұ | % | пјң0 5 |

비м»ӨмҠӨ кІҪлҸ„ | HV1(м„ёлқјлҜ№мқҳ нҠ№м„ұ) | 26 |

мҳҒлҘ | м„ёлқјлҜ№мқҳ нҠ№м„ұ | 410 |

көҙкіЎ к°•лҸ„ | MPa | 460 |

압축 к°•лҸ„ | MPa | пјһ2800 |

нҢҢкҙҙ мқём„ұ | MPa. m0.5 | 5 |

м—ҙнҢҪм°Ҫ кі„мҲҳ 25в„ғ-500в„ғ 500в„ғ-1000в„ғ | 10-6/мјҖмқҙ | 4.5 |

Thermal conductivity at 25в„ғ | W/mK | 36 |

Specific electrical resistance at 25в„ғ | м•„ cm | 1 |