Tige en céramique de zircone stabilisée à l'yttria

Tige en céramique de zircone stabilisée à l'yttria

- La description

- Demande

Tige en céramique de zircone stabilisée à l'yttria

Tige en céramique de zircone stabilisée à l'yttria

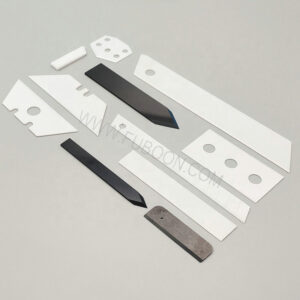

1. Zirconia ceramic rod has the highest strength and toughness at room temperature of all the advanced ceramic materials. La granulométrie fine permet des surfaces extrêmement lisses et des arêtes vives.

2. Excellent thermal insulation/low thermal conductivity (2.5 à 3 isolateurs pour dispositifs microélectroniques),

3. Very high resistance to crack propagation, haute ténacité à la rupture (6.5 à 8 MPam1/2).

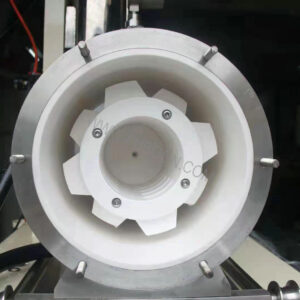

| Nom du produit | Zirconia Ceramic Rod / Small Ceramic Bar |

| Matériel | zirconia ceramic |

| Couleur | white or black ,blue or custom |

| Standard | according the request of customer |

| precision | 0.001mm |

| diamètre | 0.4-200mm |

| longueur | 5-400mm |

| Used | Refractory Zirconia Ceramic Rod / Rod Ceramic High Hardness |

Zirconia Ceramic Rod is the most widely applied and cost effective technical ceramic material. It offers a combination of superior mechanical strength and electrical properties, wear resistance and corrosion resistance. The maximum working temperature is up to 1700 °C with relatively high thermal conductivity. It is also an electrically insulating material with a high electrical resistivity. The good corrosion resistance makes it insoluble in water and slightly soluble in strong acid and alkaline solution.

Tige en céramique de zircone stabilisée à l'yttria

✔Bonne isolation électrique:

| 95% Alumine | 99% Alumine | Zircone | Carbure de silicium | Nitrure de silicium | zirconia_ceramic_parts_1 | zirconia_ceramic_parts_1 | |

| Couleur | blanche | zirconia_ceramic_parts_1 | blanche | zirconia_ceramic_parts_1 | zirconia_ceramic_parts_1 | zirconia_ceramic_parts_1 | blanche |

| Densité (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 | 2.48g/cm3 |

| Absorption de l'eau | 0 % | 0 % | 0 % | 0 % | 0 % | 0 % | 0 % |

| Dureté(HT) | 23.7 | 23.7 | 16.5 | 33 | 20 | – | – |

| Résistance à la flexion(MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa | 91MPa |

| Résistance à la compression(MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | – | 340MPa |

| zirconia_ceramic_parts_1 | 300Excellent physique | 300Excellent physique | 320Excellent physique | 450Excellent physique | 290Excellent physique | 310zirconia_ceramic_parts_1 | 65Excellent physique |

| zirconia_ceramic_parts_1 | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 | 0.29 |

| Conductivité thermique | 20zirconia_ceramic_parts_1 | 32zirconia_ceramic_parts_1 | 3zirconia_ceramic_parts_1 | 50zirconia_ceramic_parts_1 | 25zirconia_ceramic_parts_1 | 150zirconia_ceramic_parts_1 | 1.46zirconia_ceramic_parts_1 |

| Facilement dégazé | 14kilovolts/mm | 14kilovolts/mm | 14kilovolts/mm | 14kilovolts/mm | 14kilovolts/mm | 14kilovolts/mm | 14kilovolts/mm |

| Résistivité volumique(25°C) | >1014??·cm | >1014??·cm | >1014??·cm | >105??·cm | >1014??·cm | >1014??·cm | >1014??·cm |

Machining Accuracy