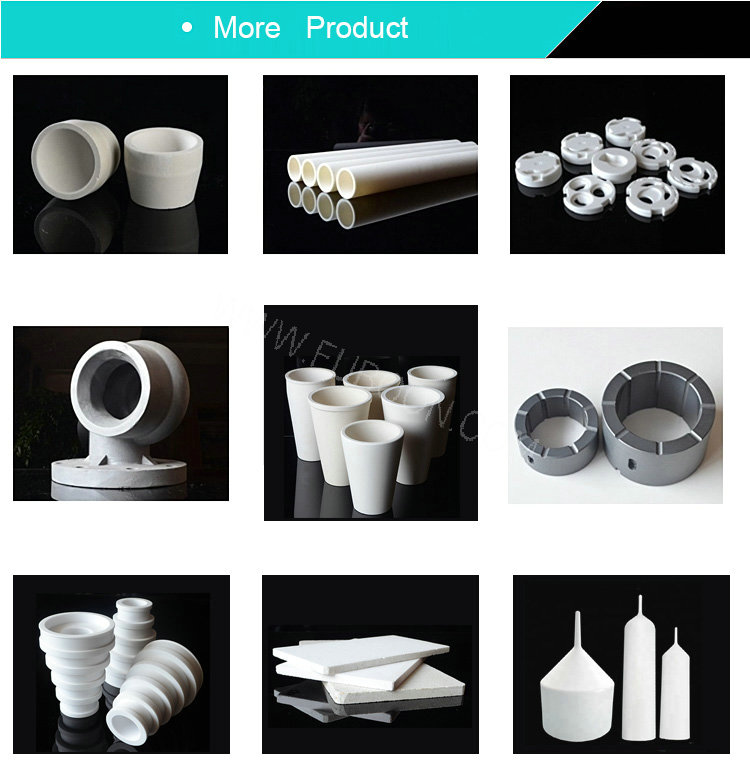

Industrielle Düse aus Aluminiumoxidkeramik

Keramikdüse zum Schweißen und Sandstrahlen

- Beschreibung

- Anfrage

Advantages of Alumina Ceramic Industrial Nozzle:

1.Long life-time cycle

2.keine Verschmutzung und scharfe Kanten.

3.Corrosion resistance.

4.Hight quality with competitive price.

Aluminiumoxid-Keramik (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. Zusätzlich, it is extremely resistant to wear and corrosion. Alumina components are used in a wide range of applications such as electronics, pump components and automotive sensors. FUBOON offers a variety of alumina compositions, einschließlich 92% Aluminiumoxid, 95% Aluminiumoxid, 96% Aluminiumoxid, 99% Aluminiumoxid, 99.5% Alumina and 99.8% Aluminiumoxid, but the 95% Alumina and 99% are the most widely used materials. Alumina components can be formed by a variety of manufacturing techniques such as uniaxial pressing, isostatic pressing, injection molding and extrusion. Finishing can be accomplished by precision grinding and lapping, laser machining and a variety of other processes.

The specifications of ceramic nozzle :

Datenblatt Technische Keramik

| Eigentum | Einheiten | Material | ||||

| 99.5% Aluminiumoxid | 99% Aluminiumoxid | 95% Aluminiumoxid | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Dichte | g/cm²3 | 3.85 | 3.80 | 3.60 | 5.95 | 5.72 |

| Wasseraufnahme | % | 0 | 0 | 0 | 0 | 0 |

| Härte | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Biegefestigkeit | Mpa | 379 | 338 | 320 | 1200 | 1200 |

| Druckfestigkeit | Mpa | 2240 | 2240 | 2000 | 1990 | 1750 |

| Bruchzähigkeit | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. Service Temperatur | ºC | 1675 | 1600 | 1450 | 1000 | |

| Côte | 1×10 -6 /ºC | 6.5~8,0 | 6.2~8,0 | 5.0~8,0 | 8.0~9,5 | 10.2 |

| Thermoschock | T(ºC) | 250 | 200 | 220 | 300 | 350 |

| Wärmeleitfähigkeit(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volumenwiderstand | Ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Isolierstärke | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielektrizitätskonstante(1MHz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Alumina Ceramic Industrial Spray Nozzle