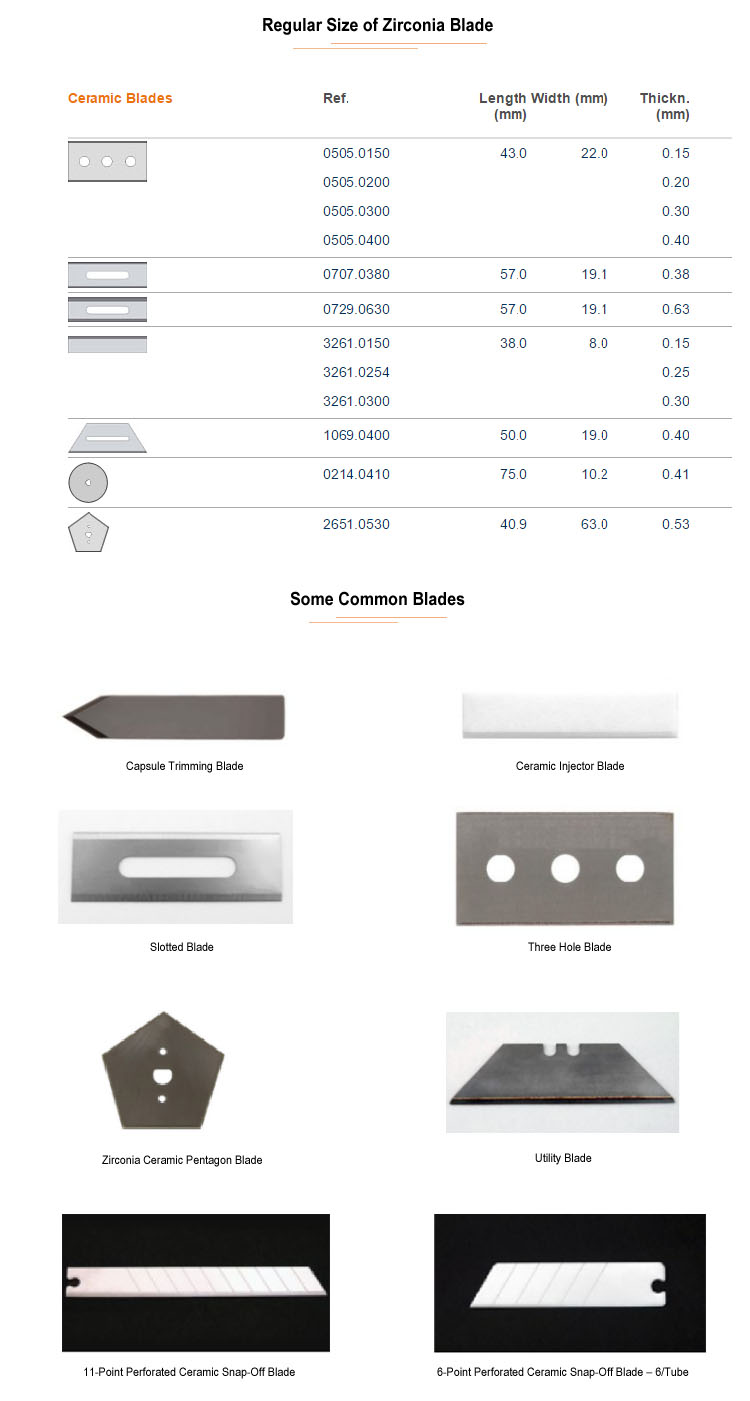

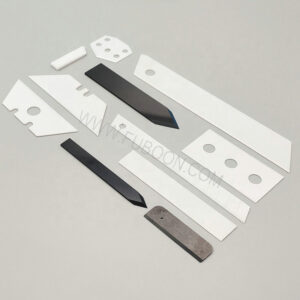

Textile Industry Precision Technical Zirconia Ceramic Cutter Blades

Zirconia textile Ceramic blade

- Description

- Inquiry

Textile Industry Precision Technical Zirconia Ceramic Cutter Blades

Fine-grained ceramics are ideal for cutting tools. Using ceramic materials substantially increase blade life and precision due to their inherent strength and wear resistance. Zirconia ceramic blades are even more brittle than Tungsten carbide blades. Ceramic blades can only be ground using diamond because of their very high hardness. We tried many different diamond wheels to find the right ones . . Fine-grain material(< 1 micron average) is 100% tetragonal . zirconia — substantially higher density than traditional ceramics.

Precision manufacturing:

Cylindricity up to 0.004mm, linear tolerance up to 0.001mm, dimensional accuracy up to 0.001mm, thread minimum machinable internal

thread M2, thickness up to 0.02mm, concentricity up to 0.003mm, minimum aperture up to 0.07mm…And other parameters.

Cylindricity up to 0.004mm, linear tolerance up to 0.001mm, dimensional accuracy up to 0.001mm, thread minimum machinable internal

thread M2, thickness up to 0.02mm, concentricity up to 0.003mm, minimum aperture up to 0.07mm…And other parameters.

Textile Industry Precision Technical Zirconia Ceramic Cutter Blades

Ceramic material composition:

· 95%–99.99% Alumina (Al2O3)

· Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

· Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

Zirconia Ceramic Properties:

Item | Value |

ZRO2 | 94.9% |

Y2O3 | 5.4% |

Hardness(HRA) | 88-90 |

Density(g/cm3) | 5.5-6.05 |

Flexural strength (MPA) | 1100 |

Young’s Modulus (Gpa) | 220 |

Thermal Expansion Coefficient(20-1000℃) (×10-6/K) | 6.5-11.2 |

Flexural Toughness(Mpa m1/2) | 12 |

Benefits:

. Safe and easy blade change

· Finger-friendly edge stays sharp 11 times longer

· Reduces injuries, lowers costs

· Safe up to 1600°C

· Ceramic blades never rust

· Ceramic blades are chemically inert

· Ceramic blades are non-conductive of electricity

· Finger-friendly edge stays sharp 11 times longer

· Reduces injuries, lowers costs

· Safe up to 1600°C

· Ceramic blades never rust

· Ceramic blades are chemically inert

· Ceramic blades are non-conductive of electricity

Application:

·Capsule cutters

·Exacto-style blades and cutters

·Medical device blades

·Receipt cutters for registers and point-of-sale use

·Knife sharpeners(Ice skates,black)

·Knife sharpeners(Ice skates,black)

·These zirconia ceramic blades are used for cutting packaging, rubber, fiber, plastics, film,

foil, mat board as well as other products.

foil, mat board as well as other products.