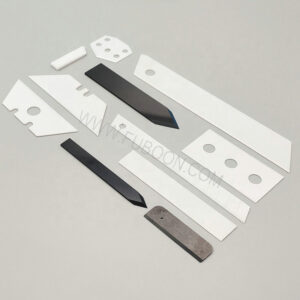

Lithium Battery Application used Zirconia Ceramic splitter

Zirconia Ceramics for Battery Applications

- Description

- Inquiry

Lithium Battery Application used Zirconia Ceramic splitter

Zirconium oxide occurs as monoclinic, tetragonal and cubic crystal forms. Densely sintered parts can be manufactured as cubic and/or tetragonal crystal forms. In order to stabilise these crystal structures, stabilisers such as magnesium oxide (MgO), calcium oxide (CaO) or yttrium oxide (Y2O3) need to be added to the ZrO2. Other stabilisers sometimes used are cerium oxide (CeO2), scandium oxide (Sc2O3) or ytterbium oxide (Yb2O3).

Advantages of Ceramic Products:

1. Refractory.

2. Self Lubricating

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Lithium Battery Application used Zirconia Ceramic splitter

·High hardness, superior impact strength, long service life, not easy to break and wear resistance.

·Non-conductive, anti-static, ceramic material itself with the insulation of electricity and magnetism properties; insulation at normal temperature, and electrical conductivity at high temperature.

·High corrosion resistance, good chemical stability, can be applied to a specific environment, such as acid and alkali resistance.

·High temperature resistance, can withstand temperatures up to 1500 ℃, with high melting point and boiling point.

·High purity Zirconia ceramics (Zro2) and Alumina Ceramics (Al2O3) material, which have advanced and excellent performances, fabulously popular.

Due to these outstanding properties, Ceramic Products are used in a wide range of industrial and advanced appications.

And a lot of practical applications prove that our ceramic products has reached a state of high standard and quality.

Zirconia ceramic can be processed in substrate, shaft , plunger, sealing structure, auto mobile Industrial parts, oil drilling equipment pieces, Insulation parts in electrical equipment , ceramic knife, ceramic hair clipper spare parts,etc, with high density, bending strength and breaking tenacity.

Lithium Battery Application used Zirconia Ceramic splitter

Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel.

high fracture toughness

thermal expansion similar to cast iron

extremely high bending strength and tensile strength

high resistance to wear and to corrosion

low thermal conductivity

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |