Silicon Nitride Tube For Automotive Engines

- Description

- Inquiry

Silicon Nitride Tube For Automotive Engines

![]()

![]()

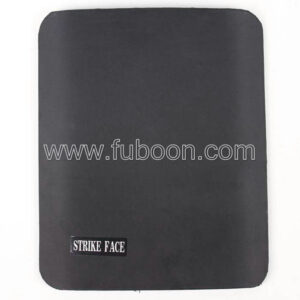

The SiC tiles are used as the ballistic armor (armour) strikeface of lightweight composite armor systems.Shield ceramics, working in conjunction with an appropriate backing system, can defeat various threats including armor-piercing rounds and IEDs. Typical ceramic composite armor systems, at approximately half the weight, outperform similar steel-based systems. These systems are frequently used in body armor, vehicle armor, and aircraft armor.

Properties:

- Low density

- High strength

- Low thermal expansion

- High thermal conductivity

- High hardness

- High elastic modulus

- Excellent thermal shock resistance

- Superior chemical inertness

Silicon Nitride Tube For Automotive Engines

Shapes and sizes for All Needs

square or hexagon shapes at various imperial and metric measurements, or let our specialists help you select custom shapes, thicknesses, and confiurations.

Advanced Ceramic Vehicle Tiles

Exceptionally well-suited for vehicular applications, FUBOON provides lightweight technical ceramictiles using tight-tolerance standards, high-purity formulations, and controlled microstructures to ensure a consistently reliable defense to unexpected threats.

The prime features of Si3N4 ceramic

1. Extraordinary thermal shock, it can withstand up to1000ºC

2. It’s easier to do precise machining, the tolerance can be 0.001mm

3. Chemical corrosion resistance under high temperature, except for HF and H3PO4

4. Extreme wear and abrasion resistance., much better than stainless steel

5. Great mechanical properties, hardness, compressive and flexural strength are much higher stainless steel

The specification of silicon nitride ceramic

| Optional material | Silicon nitride (Si3N4), Alumina (Al2O3), Zirconia (ZrO2), Silicon carbide (SiC) |

| Dimensional capability | Diameter range from 0.30 ~50 mm, length can be up to 2000 mm |

| Secondary process | Lapping, Fine grinding, Precision cutting, Tapping, Drilling and so on |

| Technical parameters | Diameter to be 0.005 mm, length to be 0.10 mm, roundness can be 0.001 mm |

| Roughness | The cylinder surface can be polished to be Ra 0.20 or better |

| Surface treatment | Diamond-like polished surface, Glazed, Metalized for ceramic to metal boning |

| Cosmetic quality | Smooth surface free of contamination, no deformation, and crack |

Silicon Nitride Tube For Automotive Engines

Description of high purity silicon nitride ceramic

Silicon nitride ceramic offers exceptional thermal shock, extreme thermal stress resistance, excellent wear resistance, great chemical resistance, and easier machinable features. It’s always made use of producing refractory ceramic parts, anti-corrosion ceramic parts, ceramic seal parts, ceramic cutter/blade for machining.

Our company supplies a great of silicon nitride ceramic components, including Si3N4 ceramic tube, Si3N4 ceramic plate, Si3N4 ceramic rod, and various complicated silicon carbide ceramic structural parts.

Application of silicon nitride ceramics:

Silicon nitride ceramic parts work as welding pins, Ceramic Shafts, Ceramic bearings, Ceramic substrates, Ceramic piston plungers, Ceramic sliders, Ceramic seal ring, Air turbine blades which are widely used in machinery, electronics, semiconductor, petroleum, chemical industry, smelting, and other industries