Si3N4 Degassing Pipe and Rotor

Si3N4 Degassing Pipe and Rotor for Aluminium foundry&casting

- Description

- Inquiry

Si3N4 Degassing Pipe and Rotor for Aluminium foundry&casting

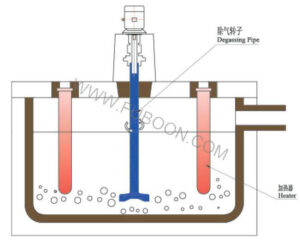

Si3N4 or Sialon/Syalon material is suitable for molten aluminum liquid degassing pipe and rotor.ln order to remove hydrogen from molten aluminum,a silicon nitride pipe is used to feed nitrogen or argon, while silicon nitride rotor is used to stir up and disperse the gas bubble, and then take the Nitrogen out with the bubble throughout the molten bath, thus get the result of hydrogen remove.

The high-temperature mechanical strength and resistance to contact fatigue of Si3N4 material assures reliable, stable and long operation of rotor in high speed rotation.

Unlike graphite, silicon nitride is hardly volatilized by oxygen at elevated temperature. This permits long operating life. And this character is most popular in the casting industry of aluminum alloy.

High thermal shock performance allows the pipe and rotor to insert in and pull out repeatedly from molten aluminum in operation. Pipes and rotors will not be cracked and damaged. Therefore, operation and maintenance become very convenient.

Excellent corrosion resistance, wear resisting and low wettability, resistance to molten aluminum liquid corrosion makes the operation life longer, and less slagging. lf proper maintenance, the using life can be up to 2-3 years.

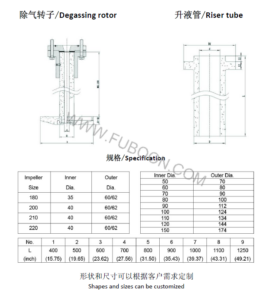

According to actual working condition,our company is able to make optimized design of rotor impeller structure to achieve better degassing effect.

Si3N4 Degassing Pipe and Rotor

Si3N4 Degassing Pipe and Rotor

1.Resistance to thermal shock

Si3N4 or Sialon/Syalon has superior thermal shock resistance and high temperature mechanical strength.

Prior to the application of Si3N4 or Sialon/Syalon products, preheating is necessary. The preheating process can realize better reliability than conventional ceramic.

2.Resistance to corrosion

Si3N4 or Sialon/Syalon has excellent corrosion resistance,being almost inert against molt aluminum, thus ensuring longer life.

3.Low- wettability

As a covalent binding ceramic,Si3N4 or Sialon/Syalon has low wettability against molten metal and does not require coating. lt will not generate much scorification and material adsorption, as a result, it is easy to clean.

4.Low heat conduction

Si3N4 or Sialon/Syalon has the advantage of low heat conduction. lts low specific heat reduces loss of heat to the minimum. This guarantees the accuracy in temperature measurement for the thermocouple protection tubes,and facilitates molten metal heat to convey in stalk tube.This can reduce the temperature of molten aluminum and save overall energy costs.

5.High strength,long life

Si3N4 or Sialon/Syalon keeps its original strength even at high temperature of up to 800°C. lts corrosion resistance and excellent strength characteristics permit a relative thin wall in thickness of the products,making it easy to handle and operate, and for maintenance and replacement.