Semiconductor Ceramics Alumina Ceramic Arm Robot

- Description

- Inquiry

Semiconductor Ceramics Alumina Ceramic Arm Robot

![]()

![]()

1.Product Composition: 99% alumina ceramic

2. Size: custom size

3. Toelrance : ±0.05mm

4. Certification: ISO9001, SGS, CTI

Product Name | Semiconductor Ceramics Alumina Ceramic Arm Robot for Wafer Handling |

Material | alumin aceramic |

Color | white |

Tolerance | ±0.001 mm |

Grade | First Grade |

MOQ | 1 pcs |

Surface Finish | Regular or Polished |

Composition | 99% alumina ceramic |

The main features of the Semiconductor Ceramics Alumina Ceramic Arm Robot

1. High precision dimensions with tightening tolerance, it’s easier to get a perfect fitting relation

2. High-temperature ability: withstand up to 1650°C in oxidizing and reducing atmospheres

3. Wear & abrasion resistance: Alumina is extreme hard technical ceramic with superb wear resistance

4. Chemical inertness, resistant most of the strong acid and alkali, and does not rust forever

5. Electrical insulation: The insulation breakdown is up to 18KV at least

6. Great mechanical properties, hardness, compressive and flexural strength are much higher stainless steel

7. Chemical corrosion resistance under high temperature, even if with strong acid or alkali

8. Protective atmospheres or high vacuum at high-temperature to eliminate contamination or impurity.

9. Low material cost in high-level applications than other technical ceramics

The specification of ceramic parts

| Material option | Alumina(Al2O3), Zirconia (ZrO2), Silicon carbide(SiO2), Silicon nitride(Si3N4) |

| Forming methods | ISO pressed, Dry pressed, Ceramic injection molding, Hot pressed |

| Specification | OD can be from 1 to 50mm, length can be from 10mm to 800mm |

| Precision processing | CNC machining, Precision grinding, Polishing, Lapping, |

| Tolerance | The tolerance of OD and ID can be 0.001mm, the tolerance of length can be 0.001mm |

| Key parameters | Roughness to be 0.02mm, Flatness to be 0.001mm, Parallelism to be 0.001mm |

| Surface quality | Free of cracks, foreign contamination, mirror surface better than Ra0.1 |

Semiconductor Ceramics Alumina Ceramic Arm Robot

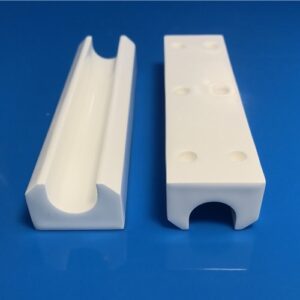

The description of high precision alumina ceramic wafer loader arm

For semiconductor devices, the critical process, as well as the parts which need to be used in a vacuum, high temperature, and corrosive gas environment, also require a clean and dustless environment. However, precision ceramic material could maintain high stability in a complicated physical and chemical environment. Semiconductor ceramic part we produced with wear resistance, corrosion resistance, low thermal expansion, insulation is made from 99.8% alumina ceramic and formed by cold isostatic pressing, high-temperature sintering, and precision machining, that’s why can meet the stringent requirements of parts for semiconductor equipment.

Semiconductor Ceramics Alumina Ceramic Arm Robot

Remark:

We have the capability with a variety of complicated geometry of high precision ceramic parts via CNC machining, precision grinding, precision drilling, and so on.

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |