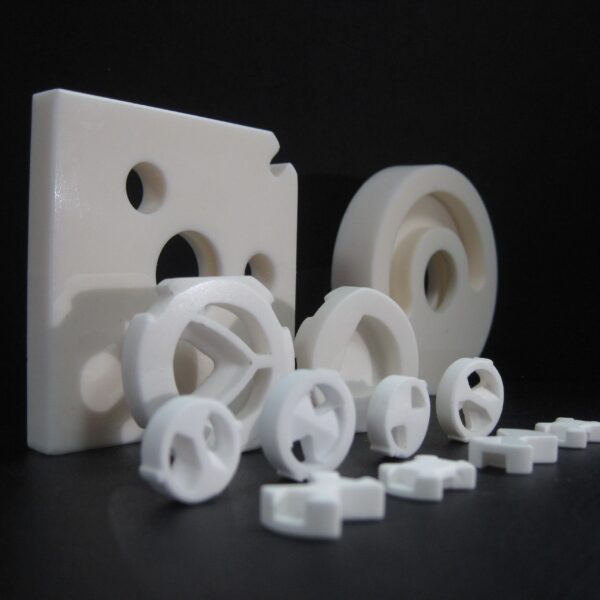

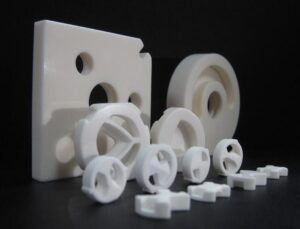

Precision Machined Zirconia Ceramic Discs

Zirconia Ceramic discs

- Description

- Inquiry

Zirconia Ceramics (ZrO2) especially Yttria Stabilized Zirconia Ceramics (Y-PSZ) is a commonly used technical ceramic material. It has relatively high fracture strength among all ceramic materials, with the addition of high hardness and low friction coefficient, it is usually used for structural ceramic components. Its thermal expansion coefficient is similar to steel, so it can be jointed to steel parts. Besides, it has excellent corrosion resistance and low thermal conductivity.

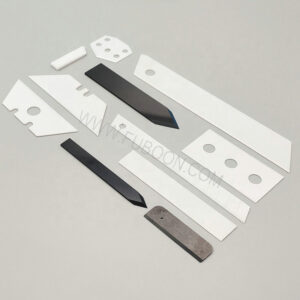

Typical applications include ceramic valve components, ceramic grinding&milling media, ceramic knife blades for various using, mechanical liners or bearing balls etc.

Precision Machined Zirconia Ceramic Discs

Datasheet of Technical ceramics

| Property | Units | Material | ||||

| 99.5% alumina | 99% alumina | 95% alumina | ZrO2 (Y-TZP) | ZrO2 (TTZ) | ||

| Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 | ≥5.95 | ≥5.72 |

| Water absorption | % | 0 | 0 | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 | 1300 | 900 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 | ≥1200 | ≥1200 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 | ≥1990 | 1750 |

| Fracture toughness | Mpa m1/2 | 4-5 | 4-5 | 3-4 | 6.5-8 | 11 |

| Max. service temperature | ºC | 1675 | 1600 | 1450 | 1000 | |

| CTE | 1×10 -6 /ºC | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 | 8.0~9.5 | 10.2 |

| Thermal shock | T(ºC) | ≥250 | ≥200 | ≥220 | ≥300 | 350 |

| Thermal conductivity(25ºC) | W/m.k | 30 | 29 | 24 | 3 | 3 |

| Volume resistivity | ohm.cm | |||||

| 25ºC | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 | >1 x 10 11 | >1 x 10 11 | |

| 300ºC | 1 x 10 12 | 8 x 10 11 | 10 12 -10 13 | 1 x 10 10 | 1 x 10 10 | |

| 500ºC | 5 x 10 10 | 2 x 10 9 | 1 x 10 9 | 1 x 10 6 | 1 x 10 6 | |

| Insulation strength | KV/mm | 19 | 18 | 18 | 17 | 20 |

| Dielectric constant(1Mhz) | (E) | 9.7 | 9.5 | 9.5 | 29 | 28 |

Precision Machined Zirconia Ceramic Discs

Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel.

high fracture toughness

thermal expansion similar to cast iron

extremely high bending strength and tensile strength

high resistance to wear and to corrosion

low thermal conductivity