High temperature sterilization ceramic plunger pump

High temperature sterilization ceramic plunger pump

- Description

- Inquiry

High temperature sterilization ceramic plunger pump

Application scope:

Applied to pharmaceutical equipment that need high-temperature sterilization ( high-temperature sterilization in 300 degrees)

Used for precision quantitative filling of liquids such as blood, biological reagent, oralliquid, injection liquid, senior cosmetics, fragrance, fungicide, etc.

Used for precision quantitative filling of all kinds of acid and alkali corrosive liquid.

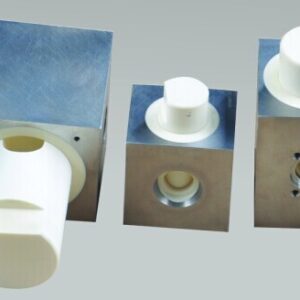

Material | Alumina 99.7%(choose different ceramic materials according to the product features),the surface is 304L316L stainless steel. | ||

Type | FUDS-02 | FUDS-05 | FUDS-10 |

Diameter of Plunger | 8mm | 13mm | 18mm |

Filling accuracy | ±2.5% | ||

Filling capacity | 0.5ml/rev | 1.5ml/rev | 3ml/rev |

High temperature sterilization ceramic plunger pump

1. Ceramic plungers are made of high-performance ceramic materials, which have the advantages of high hardness, high wear resistance, high temperature resistance, corrosion resistance and no pollution to materials.

2. Among various metering pumps, ceramic pumps have the highest accuracy, which can reach ±3%, and maintain long-term stability and high repetition consistency.

3. The micro-porous structure of ceramic plunger working face obtained by unique processing means has self-lubricating effect and no sealing ring is needed.

4. The surface of cavity and plunger is machined into mirror by advanced high-precision internal and external grinder. The surface of cavity is made of fluid structure without dead angle and groove, which is convenient for cleaning and disinfection.

5. The pump body structure is made of 316L stainless steel, which is connected with ceramics through a specific process.There are no other impurities and it is easy to disassemble.

The product has been tested for corrosion resistance, acid and alkali resistance and safety performance