Alumina Ceramic Sintering Setters For Electronic Component

- Description

- Inquiry

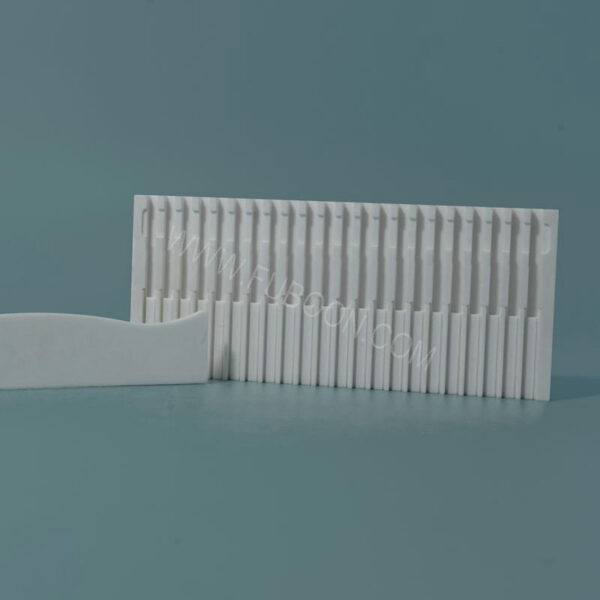

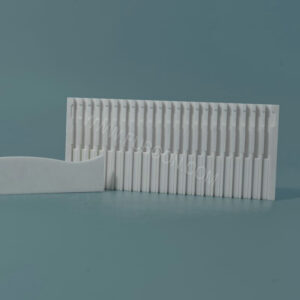

Alumina Ceramic Sintering Setters For Electronic Component

The description of high precision alumina ceramic parts,Alumina Ceramic Sintering Setters

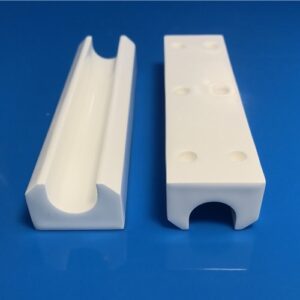

Alumina (Al2O3) is a hard-wearing technical ceramic material frequently used in a broad range variety of industries applications. After firing and sintering, the alumina ceramic parts can only be precisely machined using diamond-grinding methods. It’s charactered by high tighten tolerance, high hardness and wear resistance, low erosion levels, high-temperature resistance, corrosion resistance, and chemical stability. Furthermore, it can be highly polished making it a mirror surface to reduce friction at the fitting, working status.

We offer a selection of purities ranging from 95 – 99.8%. Our factory has access to many different types of shaping methods, including dry pressing, hot pressing, ceramic injection molding, ISO pressing, tape casting, and extruded.

Our facility is capable of machining a variety of complicated ceramic parts with a very high accuracy dimension through fine grinding, lapping, CNC machining, laser cutting, and so on.

High purity alumina setters are ideal for quality improvement and cost reduction.

Since high purity Alumina has excellent corrosion resistance and thermal shock resistance, it is used for setters for sintering and heat treatment.

Main features

- Sintering ceramic setters for electronic component materials

- Ceramic setters for heat treatment of metal products

- Ceramic jigs for brazing process, etc.

Alumina Ceramic Performance Item Unit 95 Al2O3 96 Al2O3 99 Al2O3 Physical Characteristics Heat resistance ℃ 1500 1550 1800 Bulk dnsity g/cm³ 3.6 3.6 3.9 Water absorption % 0 0 0 Mechanical Characteristics Flexural strength Mpa 320 340 360 Hardness vickers Gpa 12.2 13.5 15.6 Elastic mdulus Gpa 280 320 370 Poisson’radio 0.22 0.23 0.23 Thermal Characteristics Linear expansion coeffcient (20-500℃)10^-6/℃ 7.1 7.2 8 Thermal conductivity w/(m.k) 16 24 32 Specific heat *10^-3(kg*K) 0.78 0.78 0.9 Electrical Characteristic Dielectric constant(1MHZ) – 9 9.4 9.9 Dielectric loss angle *10^-4 15 5 1 Dielectric strength *10^6V/m 12 15 15

Application

Since high purity Alumina setters has excellent corrosion resistance and thermal shock resistance, it is used for setters for sintering and heat treatment.

Alumina ceramic is a kind of structural ceramics, with insulation resistance, voltage resistance, high strength, good thermal conductivity, dielectric loss, stable electrical performance characteristics. Used in electronic ceramic substrates, ceramic electrical insulation, vacuum devices, devices porcelain, spark plugs and other products.

Alumina ceramic screw

Feature:

- A variety of specifications available

- Satisfy various technical request

- Lower medium spoilage

- Good insulation performance and high temperature resistance

- Stiffness texture

- Used in all electric products, electric heating products and wear resistant machinery parts