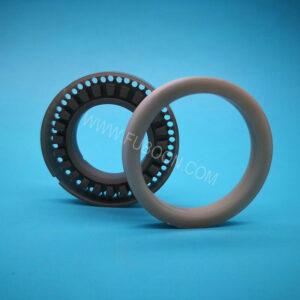

AlN Aluminum Nitride Ceramic Crucible

- Description

- Inquiry

AlN Aluminum Nitride Ceramic Crucible

The aluminum nitride (ALN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low

dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic,

high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is

widely used in communication components, high power led, power electronic devices and other

fields.Special spec products can be produced upon requests.

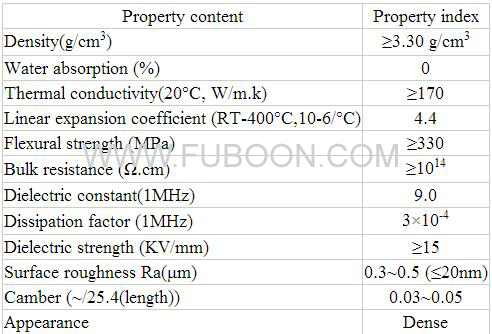

PRODUCT PERFORMANCE

– High thermal conductivity, high flexural strength, high temperature

– Good electrical insulation

– Low dielectric constant and loss

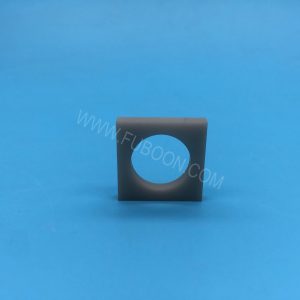

– Able to be laser drilled, metallized, plated and brazed

AlN Aluminum Nitride Ceramic Crucible

With its properties of electrical insulation and excellent thermal conductivity, Aluminum Nitride Ceramics is ideal for applications where heat dissipation is required. In addition, since it offers a coefficient of thermal expansion (CTE) near that of silicon, and excellent plasma resistance, it is used for semiconductor processing equipment components. Advantages: · High thermal conductivity combined with good electrical insulation characteristics. · Exceptional stability when exposed to many molten salts. · Thermal stability up to at least 1500°C · Favorable mechanical characteristics extending into the high temperature range. · Low thermal expansion and resistance to thermal shock. · Special optical and acoustic characteristics. | ||||

Physical Properties | ||||

· Flexural strength is 300 ± 5MPa · Coefficient of thermal expansion is 5.6×10-6K-1 (20-1000°C) · Thermal conductivity is 70-180 W/m.K · Insulation resistance is >1012Ωcm (20°C) |

· Cold Isostatic Press

· Dry Press

· Tape Casting

· Precision Machining Processing

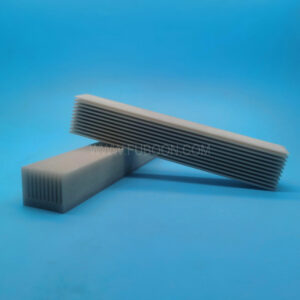

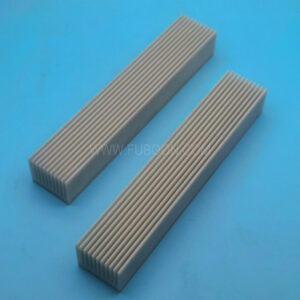

· AlN Ceramic Heat-sinks for high power system

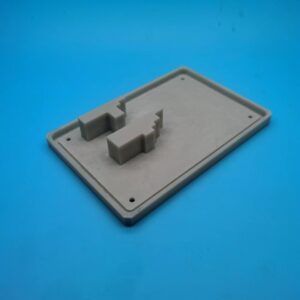

· AlN Crucible for Metal Melting

· AlN Ceramic Rod

· AlN Ceramic Heater

· Ceramic Substrate

· Custom Shape